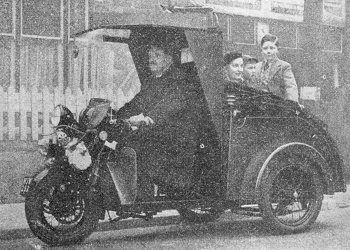

THE TURNER BY-VAN, TRI-VAN & RIXI

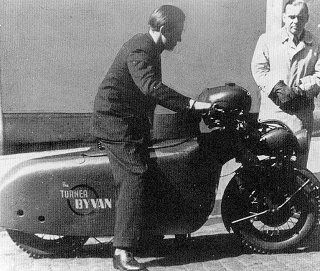

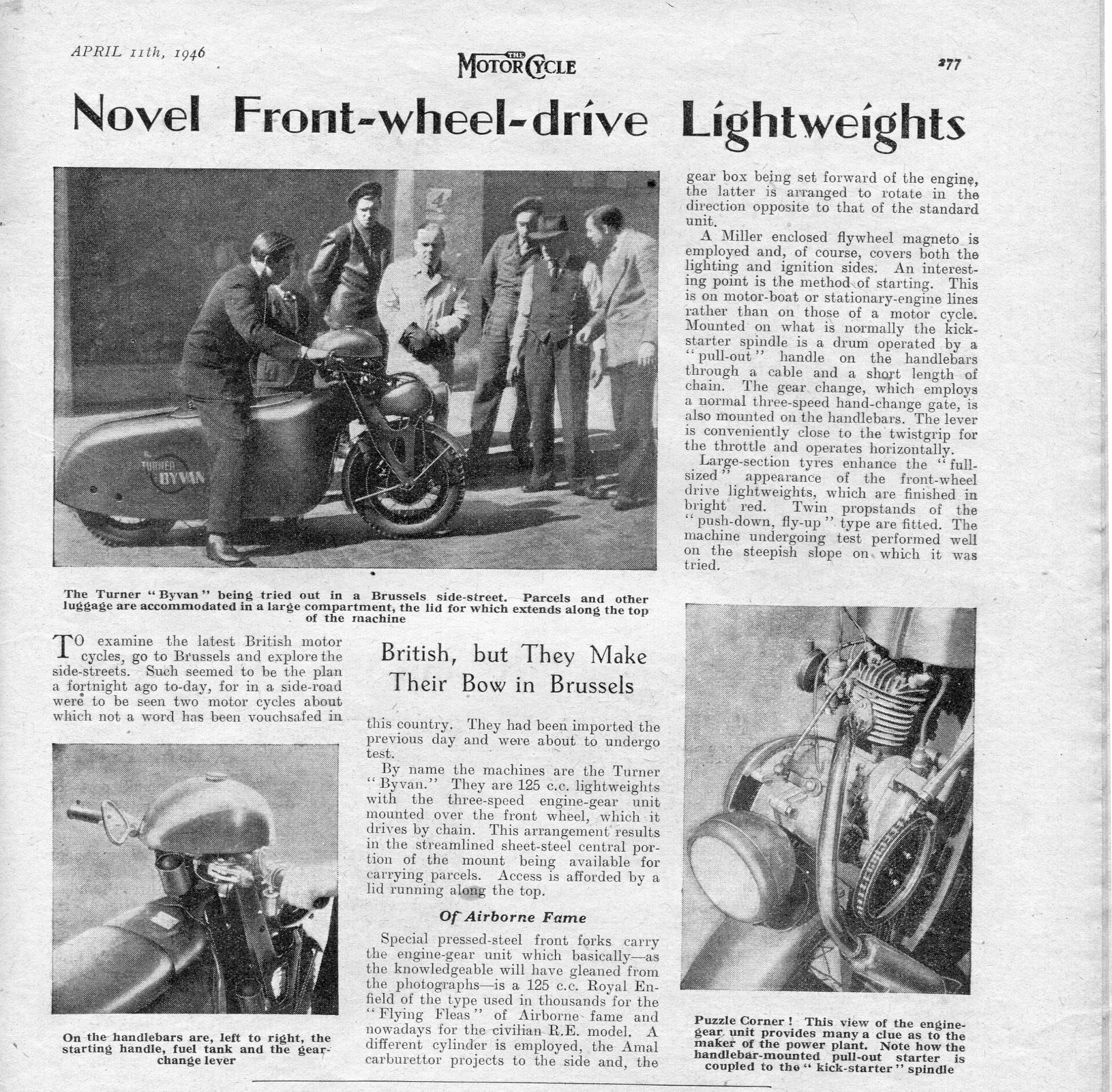

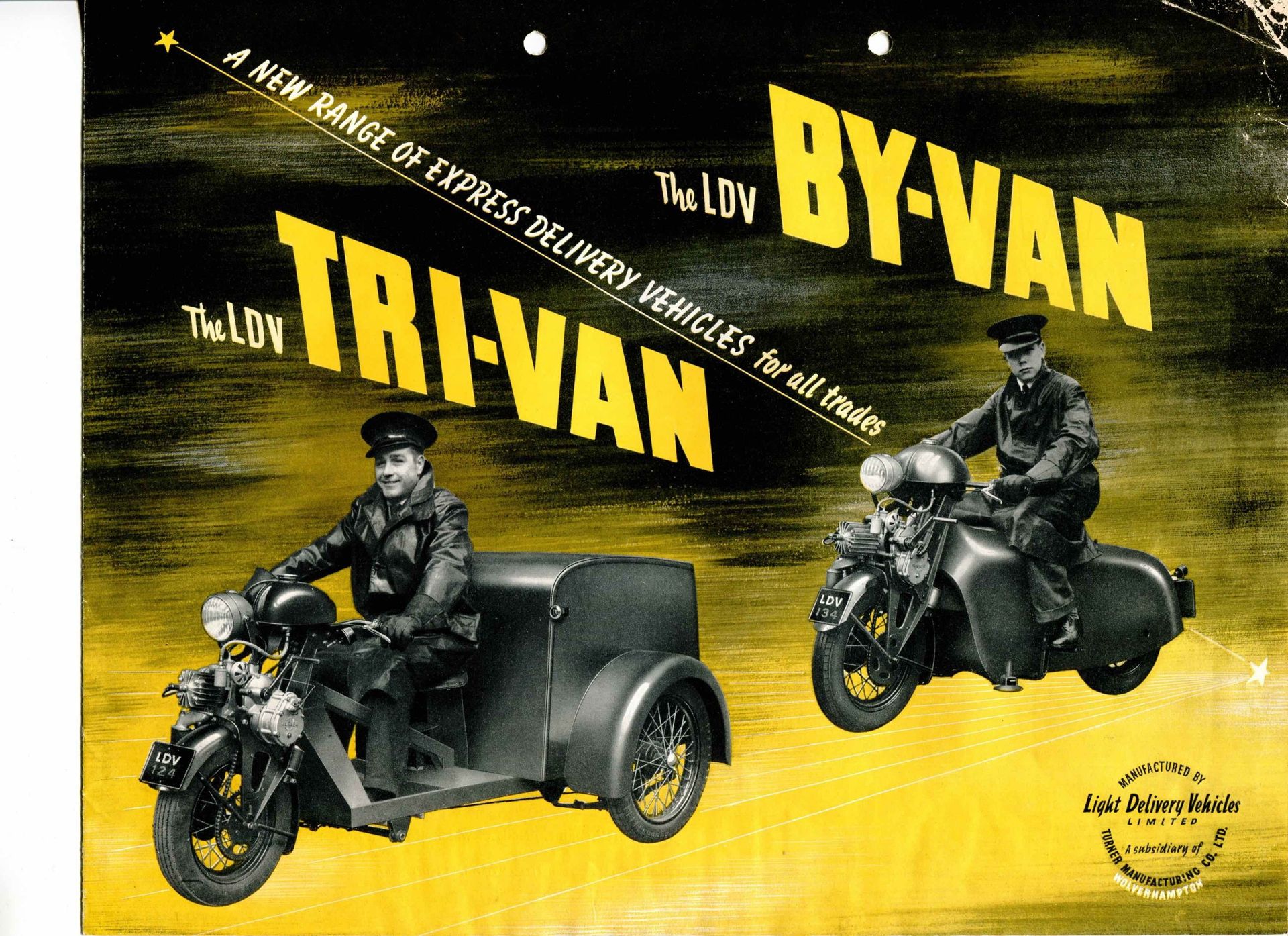

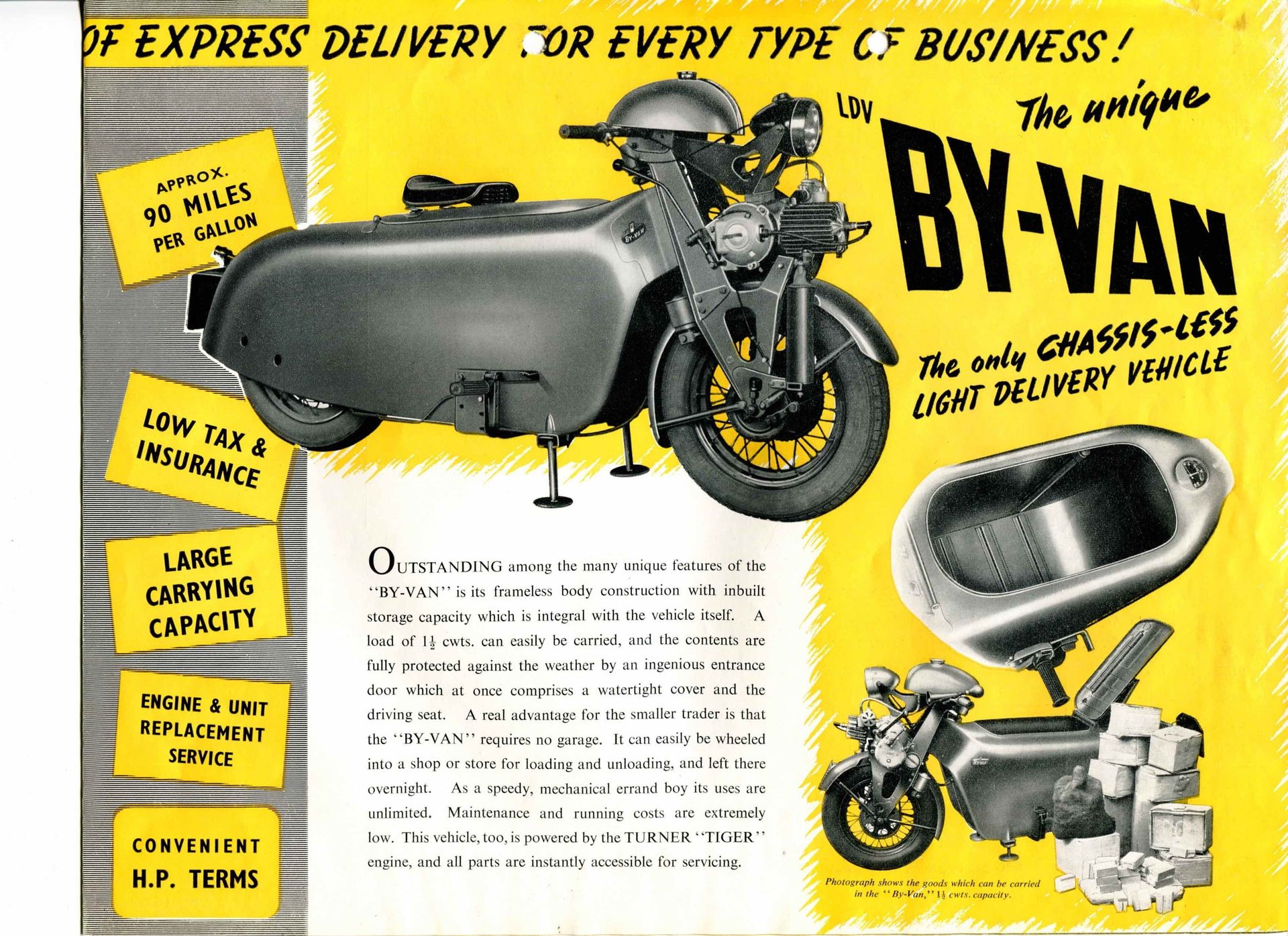

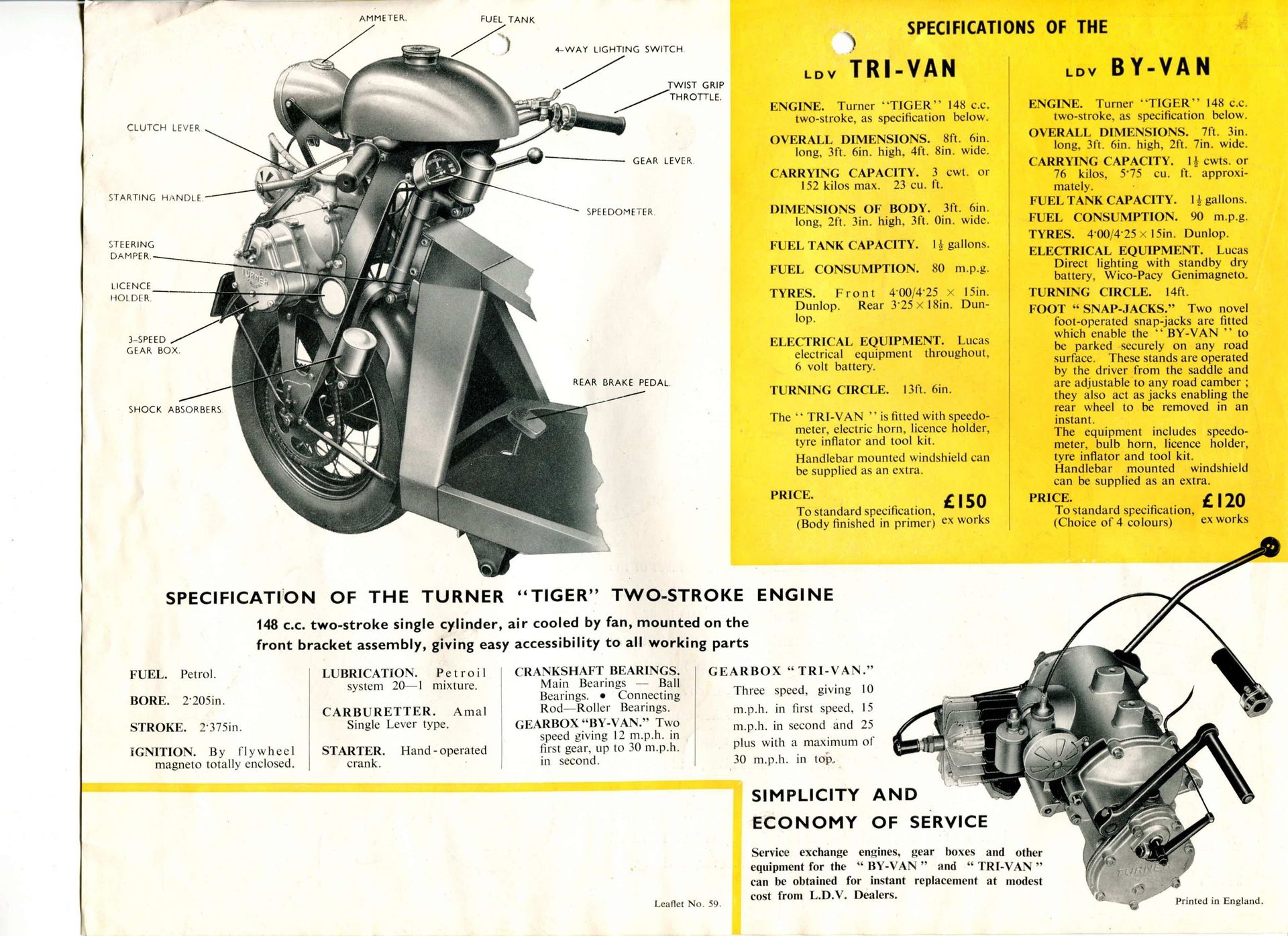

The By-van and Trivan (there was also a rickshaw like version of the Tri-van known as the Rixi as shown below), two models of an interesting type of lightweight delivery vehicle have been introduced by the Turner Manufacturing Co. Ltd., Wulfruna Works, Villiers Street, Wolverhampton. The outstanding feature of the design lies in the mounting of the engine and transmission system as an integral part of the front-wheel assembly.

With the exception of the gearbox, the chassis specification is common to both types.

All three devices:-

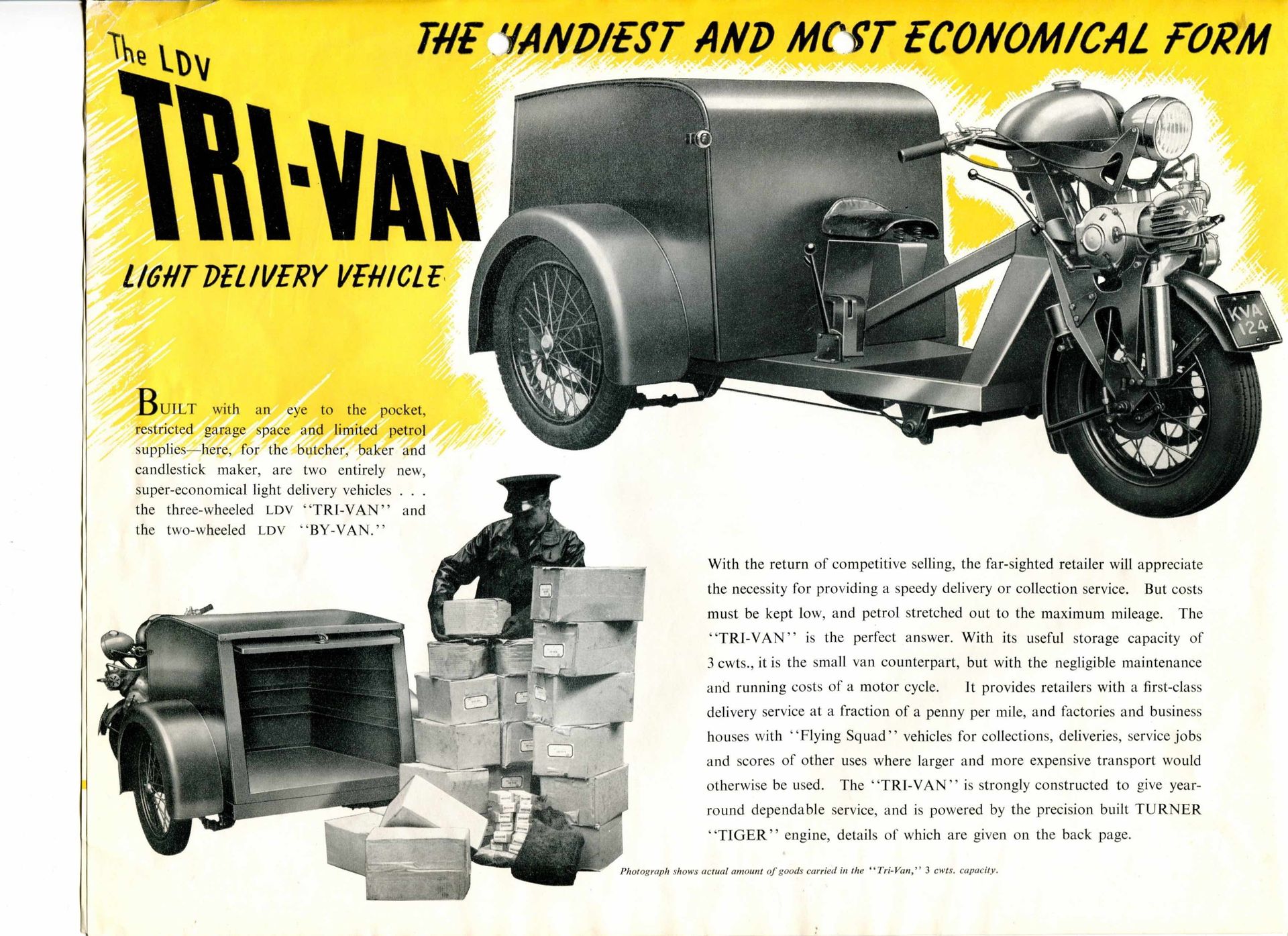

The three-wheeler has a fabricated steel frame with a coachbuilt body mounted behind the driver, who sits on a pan seat with his legs one on each side of a frame member. The power unit is a Turner Tiger 148cc single cylindered air-cooled two-stroke, mounted horizontally above the front wheel.

With the exception of the gearbox, the chassis specification is common to both types.

The three-wheeler has a fabricated steel frame with a coachbuilt body mounted behind the driver, who sits on a pan seat with his legs one on each side of a frame member. The power unit is a Turner Tiger 148cc single cylindered air-cooled two-stroke, mounted horizontally above the front wheel.

Cooling is assisted by a fan in conjunction with a system of cowling.

Ignition is by a flywheel magneto, and the engine is lubricated on the petroil system.

The Tni-van has a three speed gearbox, and the By-van a two-speed unit. A chain takes the drive from the gearbox to the front wheel, the clutch control being on the handlebars and the gear control, in the form of a lever, on the front fork assembly.

Rear suspension on the Tri-van is by quarter-elliptic springs with Silentbloc bushes in the eyes, whilst at the front, rubber shock absorbers are used. Similar shock absorbers are employed at the front and rear on the By-van. The rear tyres on the Tri-van are 3.25 by 18” Dunlops with 4 or 4.25 by 15” on the front wheel. The latter size of tyre is used on the front and rear wheels of the By-van.

The body on the By-van is of the pannier type and of pressed-steel construction. It has a capacity of about 5.75 cubic ft., the machine being designed for loads up to 1 k cwt. When standing, the machine is supported on two legs which can be brought into use by the driver from the saddle.

Fuel consumption for the Tri-van is stated to be 75mpg., and for the By-van 80mpg. These figures, of course, would be governed by the type of service involved.

The following pictures are of a Trivan sold in California:-

11th April 1946 Motor Cycle Byvan

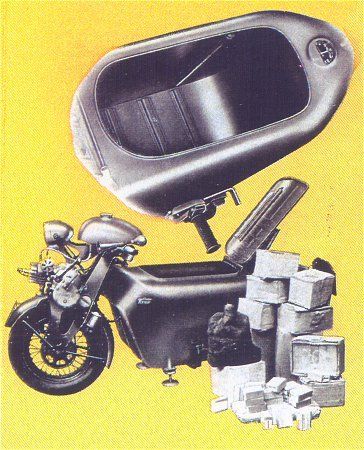

TURNER BYVAN & TRI-VAN BROCHURE

I have recently come in to possession of a promotional brochure as below:-

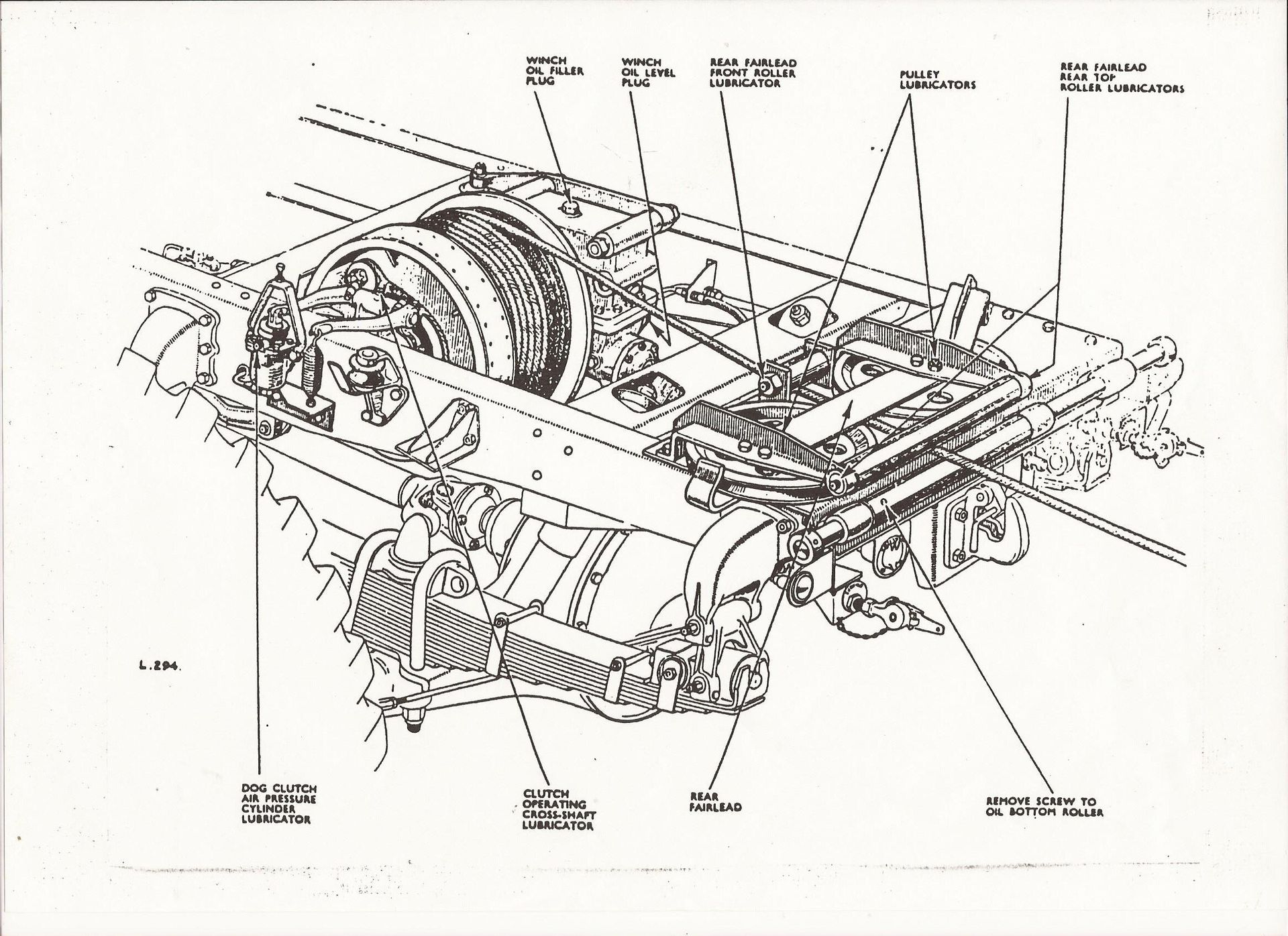

Winches

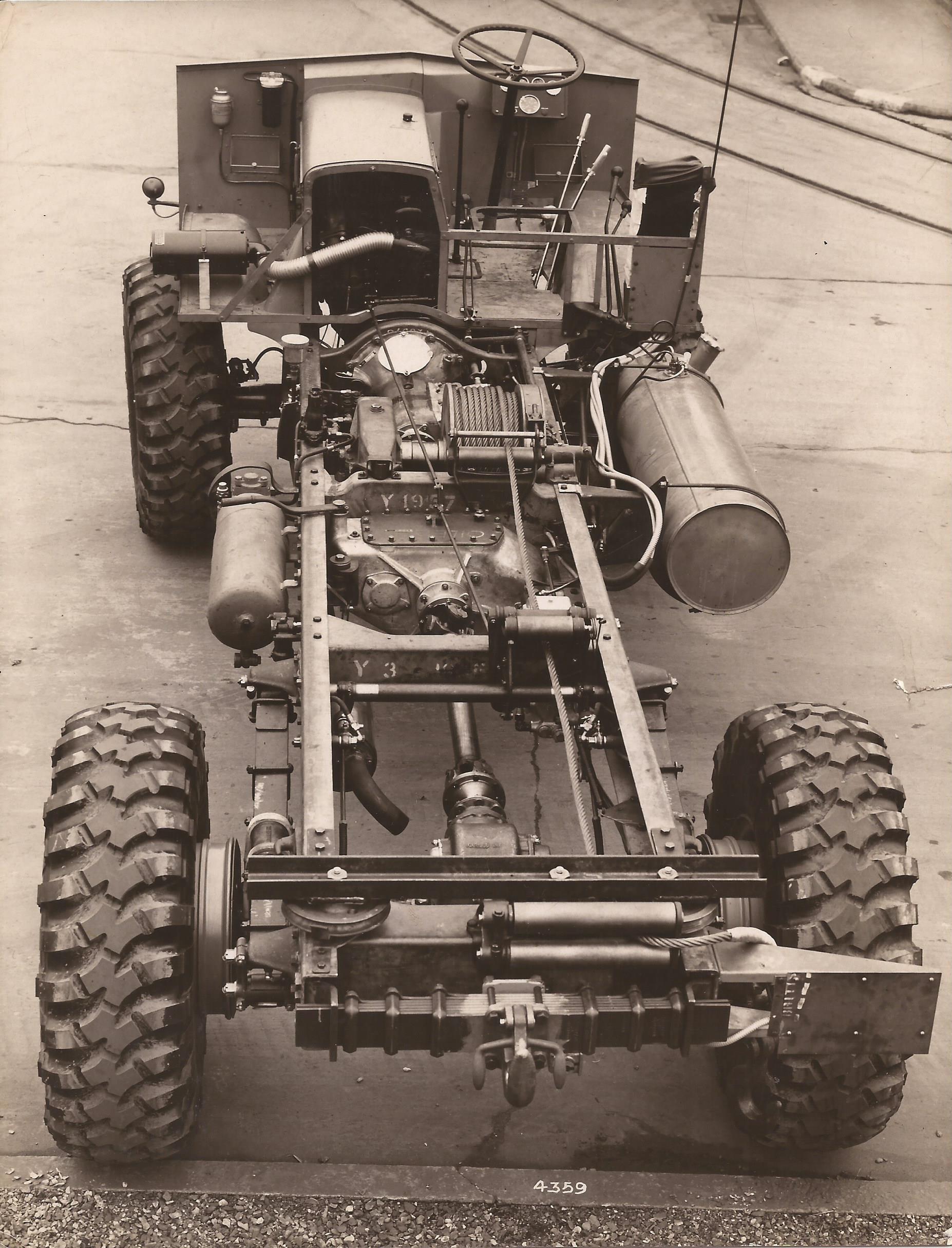

The first Turner winch was developed for use in a Guy Motors truck built in 1927.

The military wanted a winch fitting to the AAX truck to help with handling field guns and for the recovery of the vehicle. Since then Turners have supplied a large variety of recovery winches for many different military vehicles. Some typical examples are noted below.

Bedford were one of the first vehicle makes to be fitted and this association continued from the WW2 vehicles through the RL to the TK based MK with the last vehicle being the tilt cab TM.

AEC were also a major customer with the Matador being the best known.

One of the three winches fitted to the Scammell Pioneer 6X6 recovery vehicle is a Turner unit. The main recovery winch is a Scammell design but the winch over the jib is a Turner unit with the jib being raised and lowered by a Morris unit.

Humber vehicles and Daimler Scout cars were fitted with a 2 ton winch.

The largest winch ever produced by Turners was the 20 ton unit winch was used in the Thornycroft Antar MK3 tank transporter and, with hydraulic drive, in the Leyland Martian recovery vehicle.

(I'd like to acknowledge the Vintage Spirit magazine for the above photo)

The smallest winch of one ton capacity ('Mini Winch') was available in cable and capstan formats and was produced for the Austin Gipsy and Land Rover range of vehicles.

Turner also produced a smaller winch the 'Mini Winch' as shown below (more details to be provided when I get the chance):-

This next image is taken of a Turner winch brochure.

The following pictures were supplied in October 2021 of what is a quite rare winch (certainly the only known survivor of about 6 made) as designed by Turners to fit the Thornycroft Antar replacement, the Scamell Commander.

Turner Cars

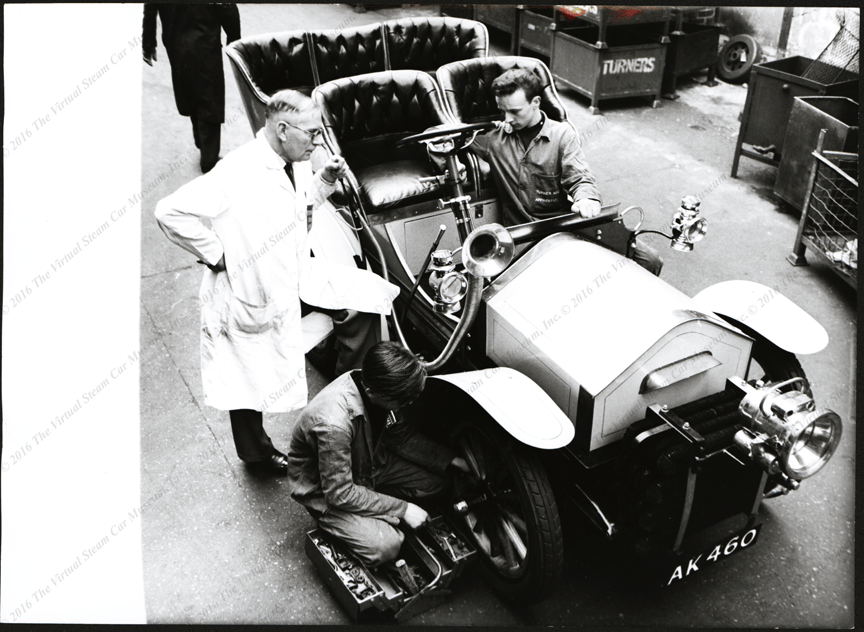

This press photograph, dated September 22, 1965, shows one of two surviving Turner-Miesse Steam Cars following its restoration at the Turner Manufacturing Company, Ltd., in Wolverhampton (with credit to the virtuasteamcarmuseam.org site)

Turner chassised Varley Woods cars:-

Up to dat'ish photo of a Varley Woods car:-

The picture below is of another rare Turner car, a 1914 TURNER 4 cylinder 12/20 HP 2 seat open tourer which was posted for sale on eBay in March 2015.

The advert below is a period one for a slightly later vehicle then the one above:-

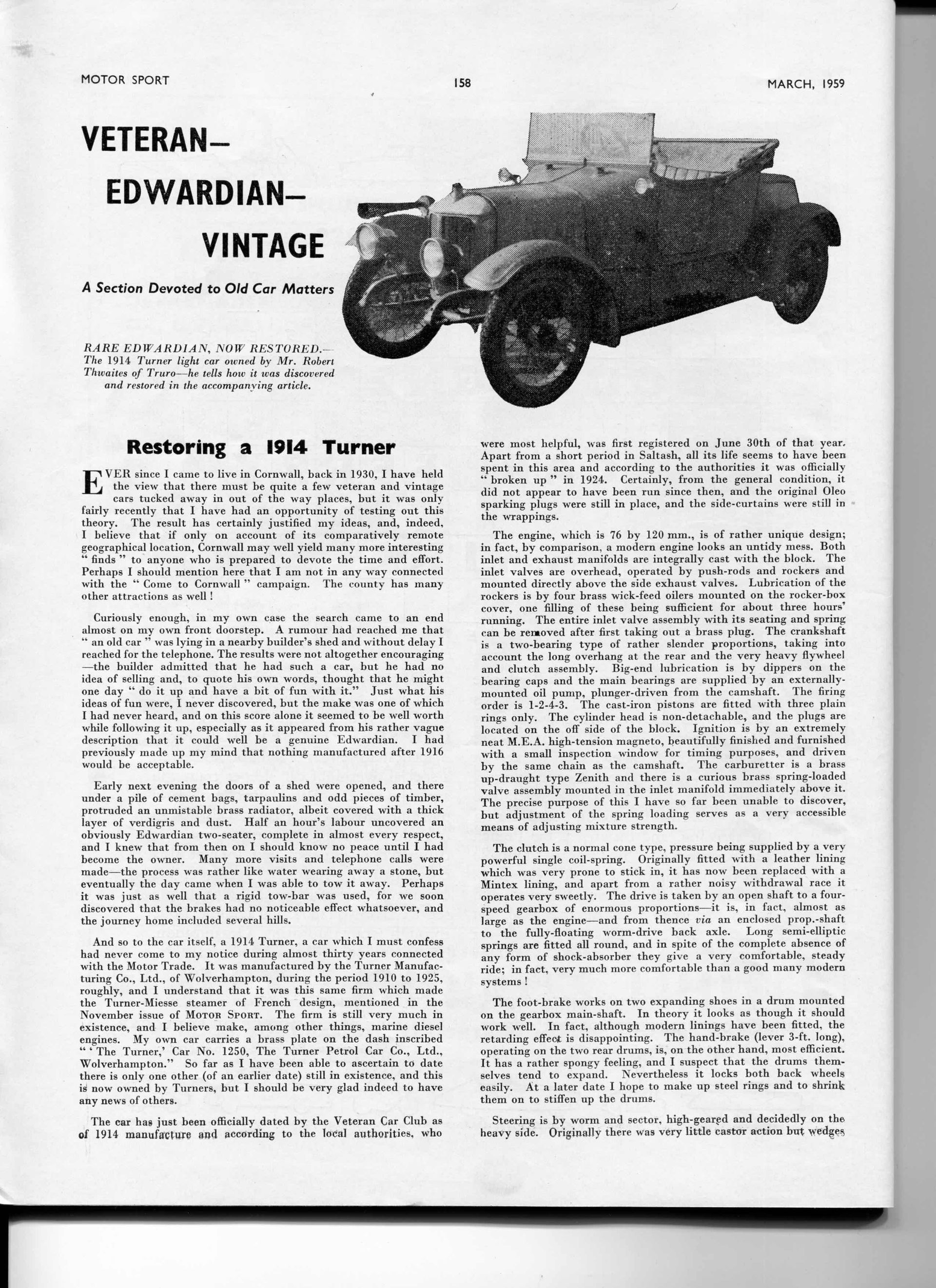

Having recently discovered the existence of the above Turner car I also became aware of an article referring to its restoration that appeared in the Motor Sport magazine of March 1959 as below:-

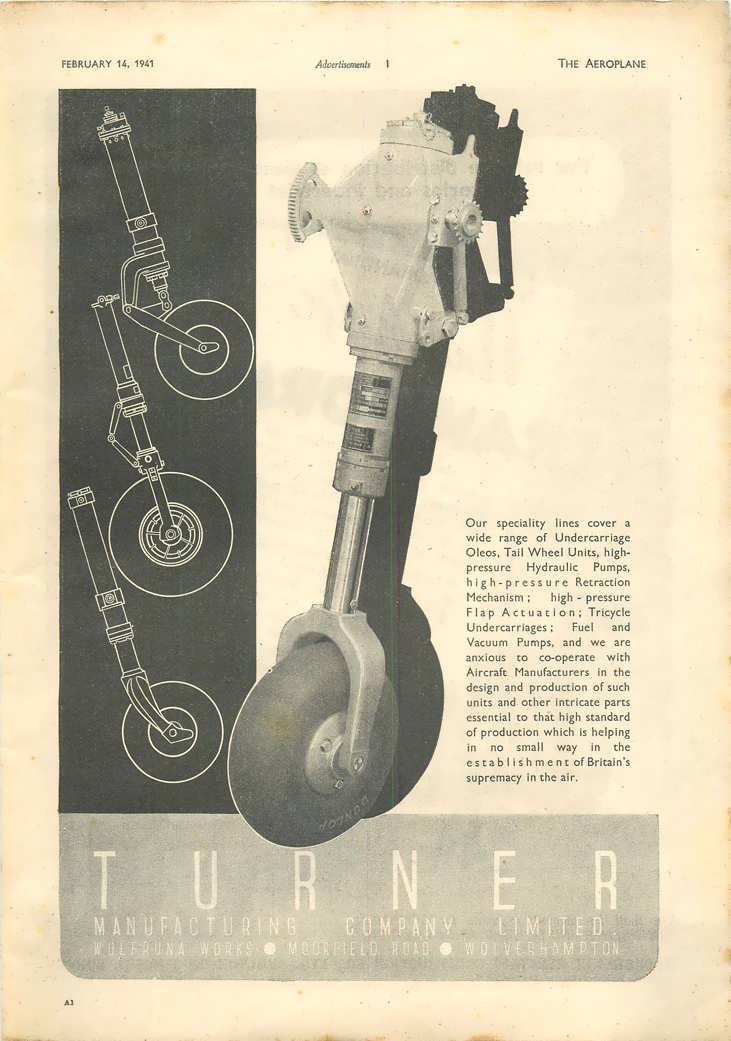

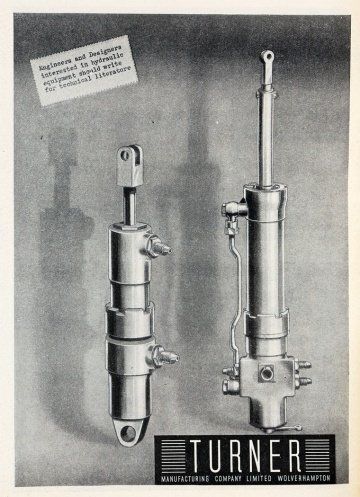

TURNER AIRCRAFT PARTS

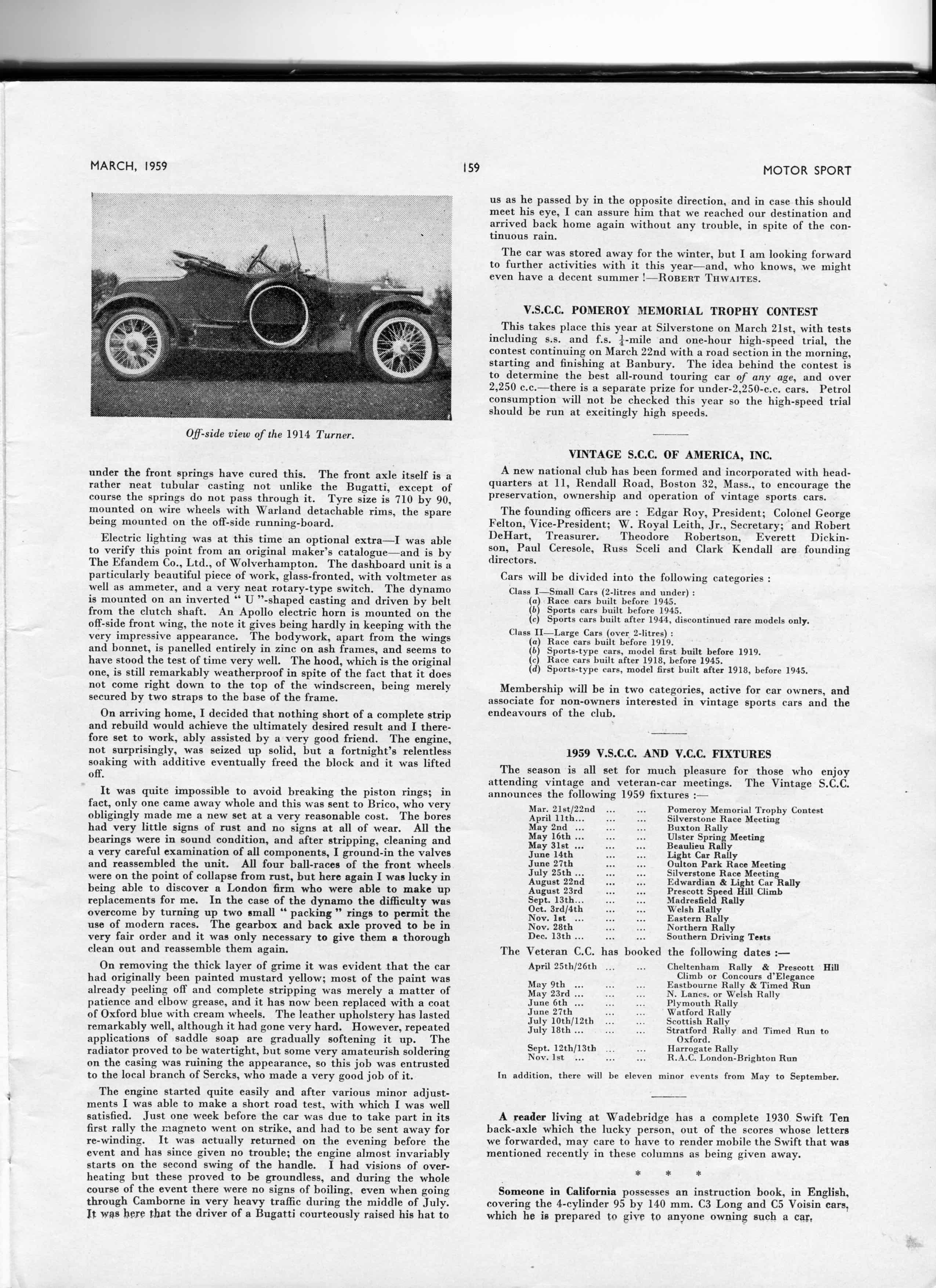

I don't have a great deal of information about this part of Turner's business. I purchased what has proven to be a vacuum pump in September 2017, a picture of which appears below along with a number of Turner aircraft related adverts.

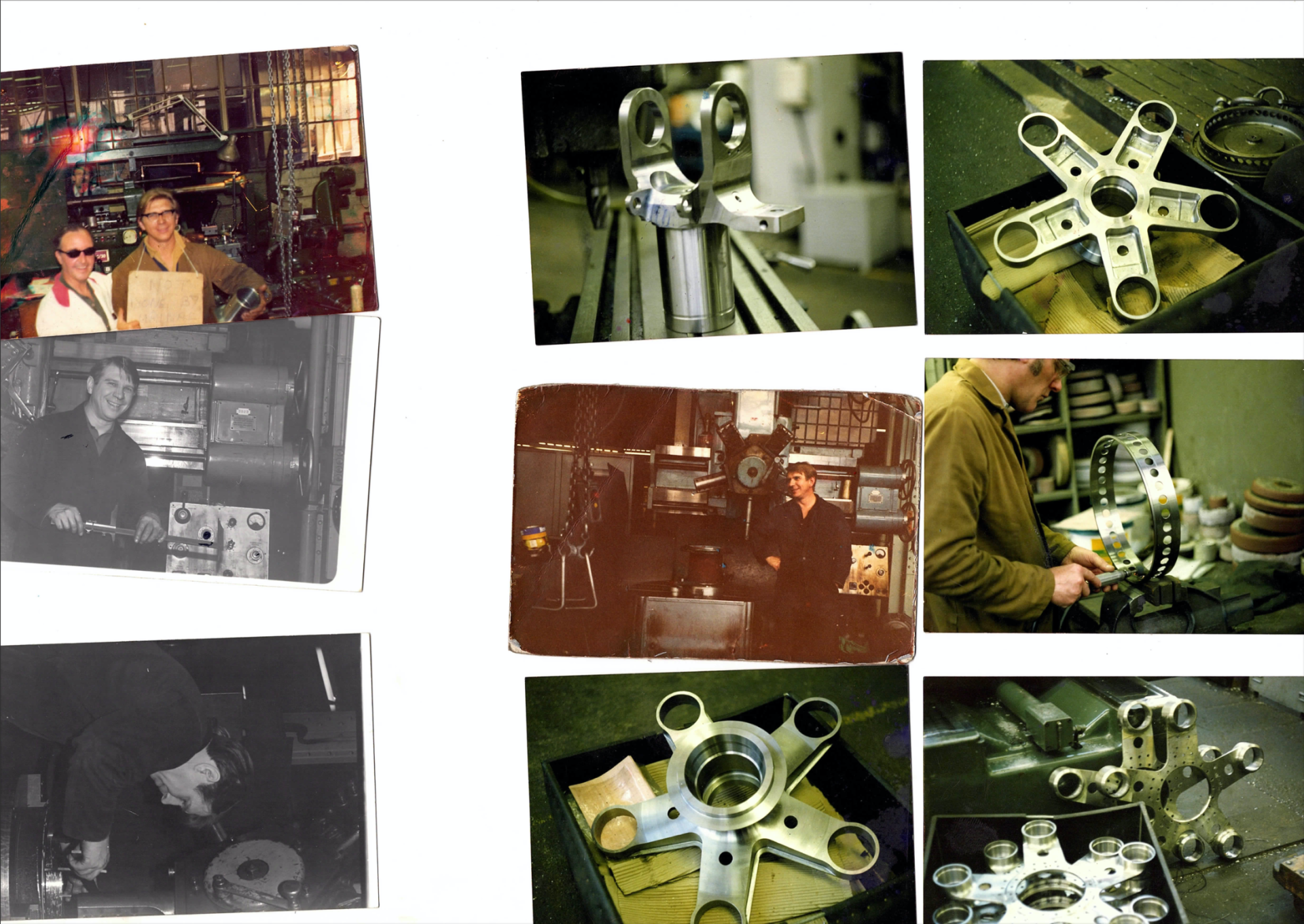

The 'collage' below was supplied by the son of a former Turner employee who worked at the aircraft machine shop, Moorfield Road producing parts for the Westland helicopter:-

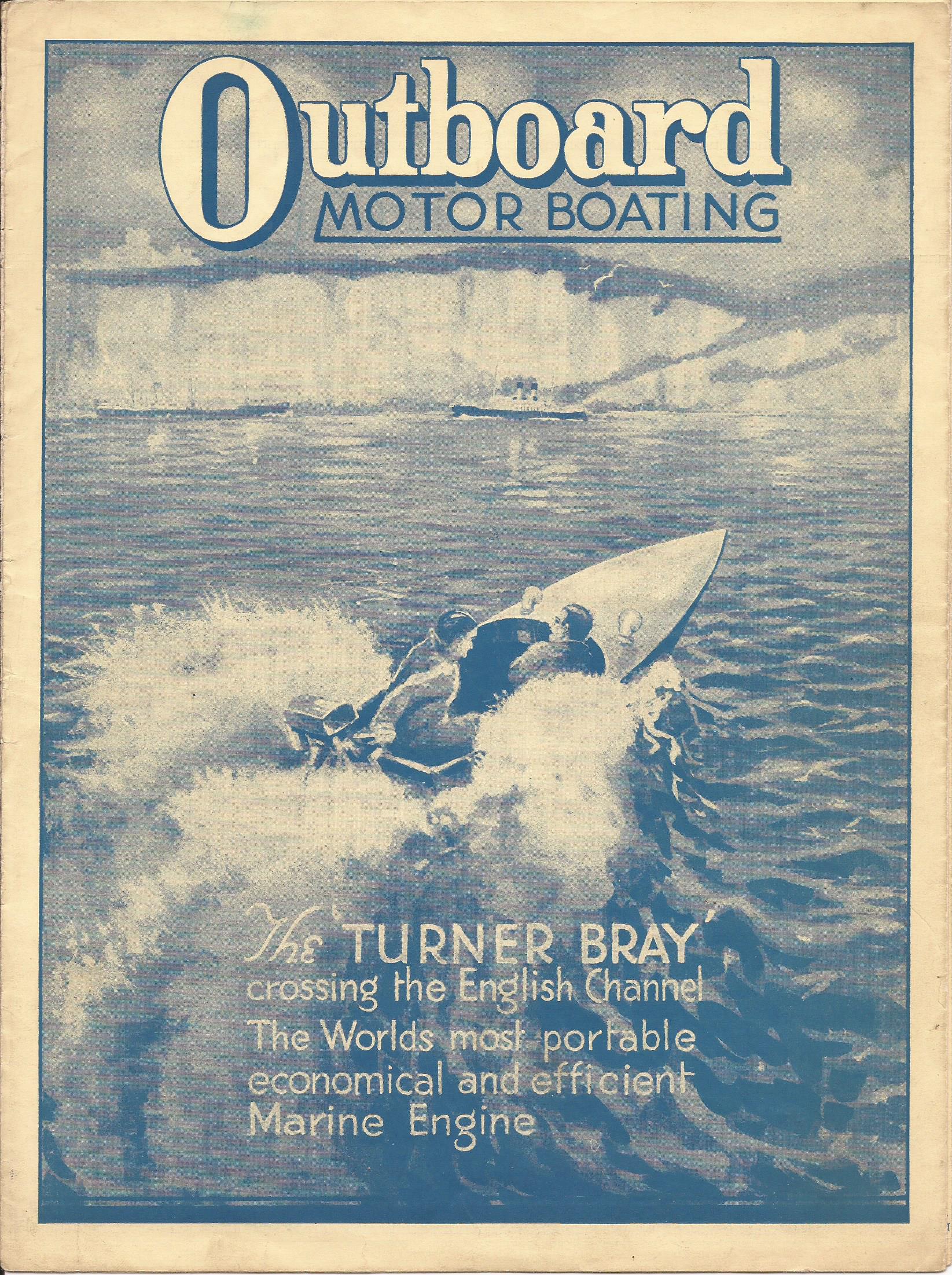

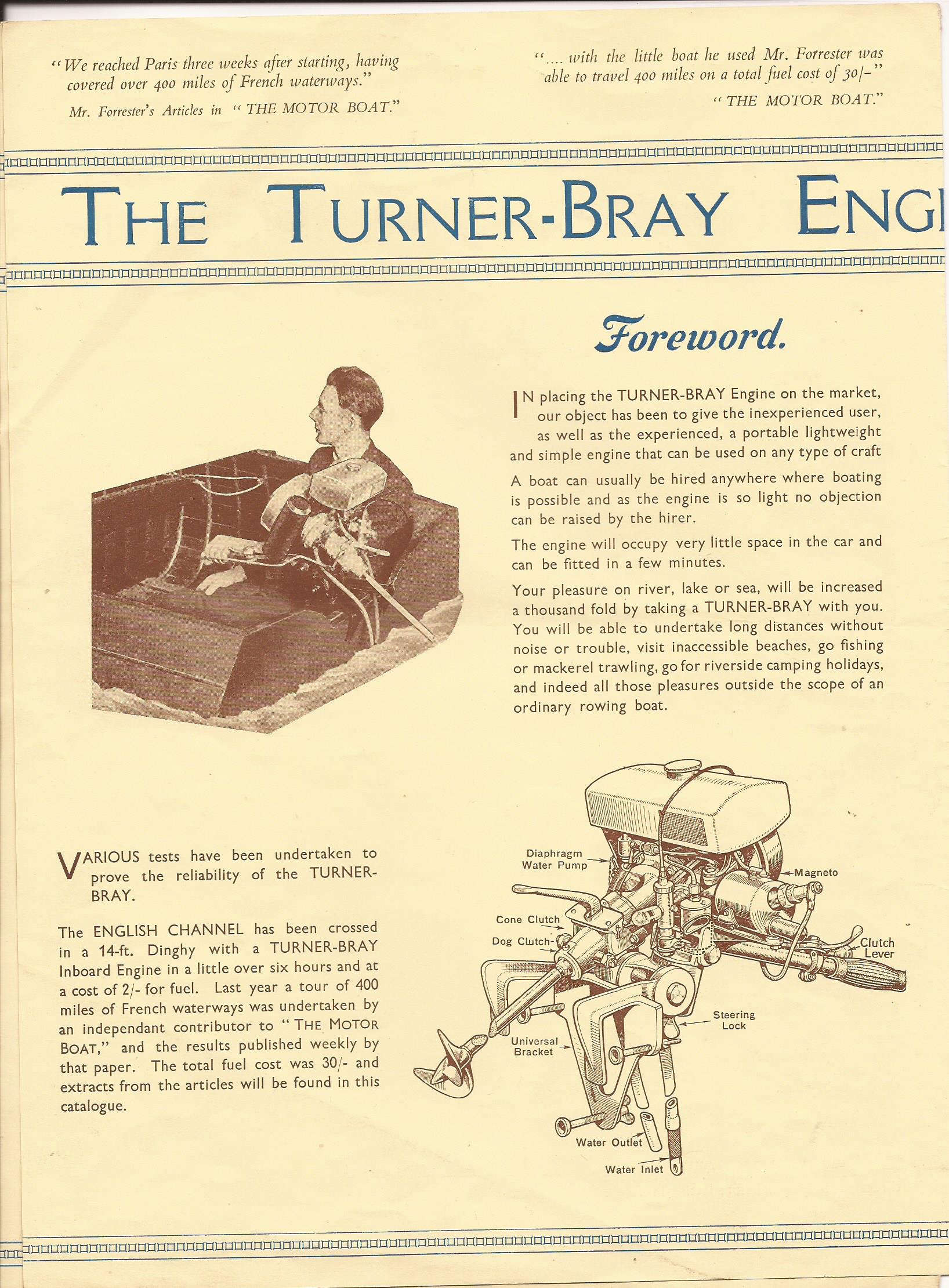

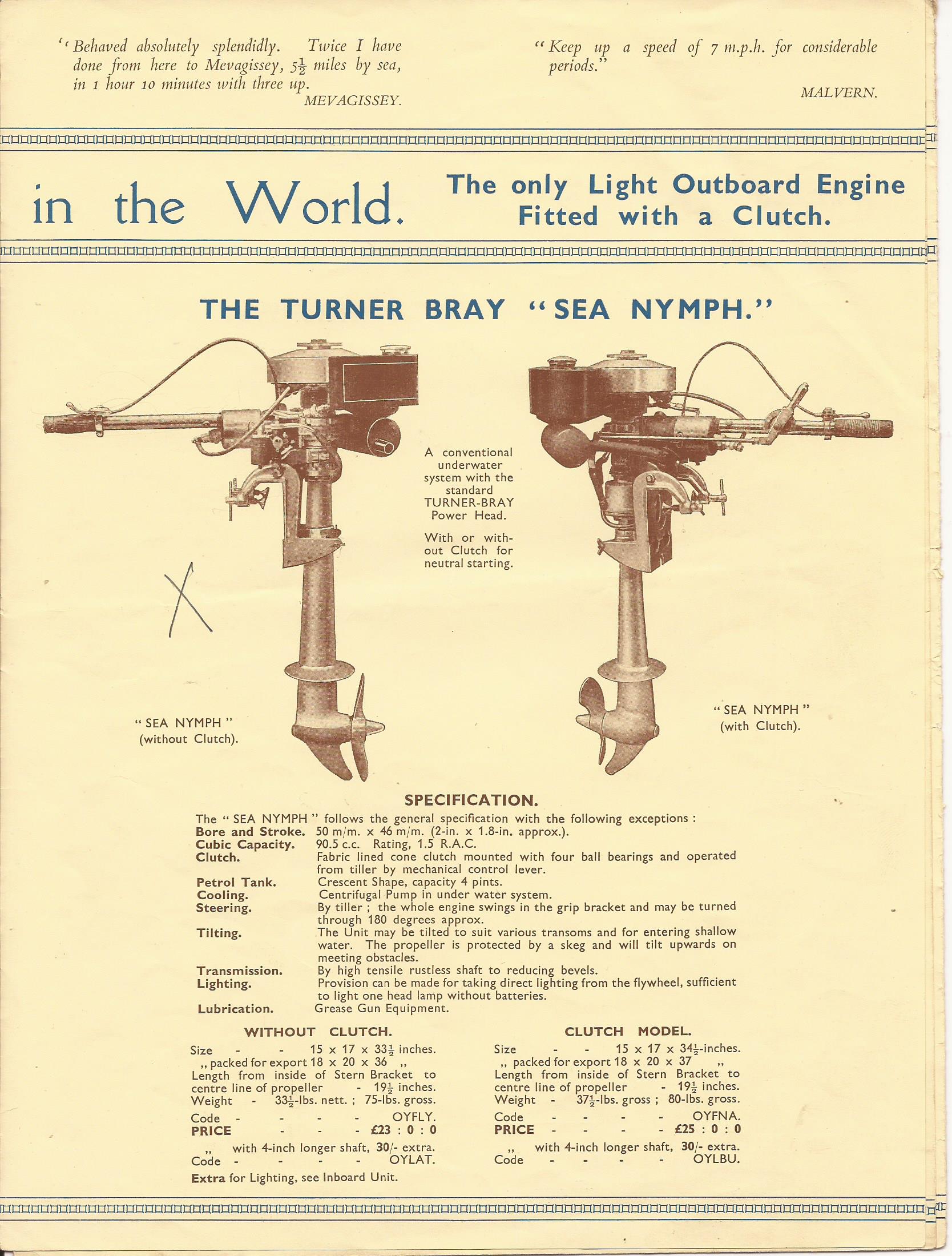

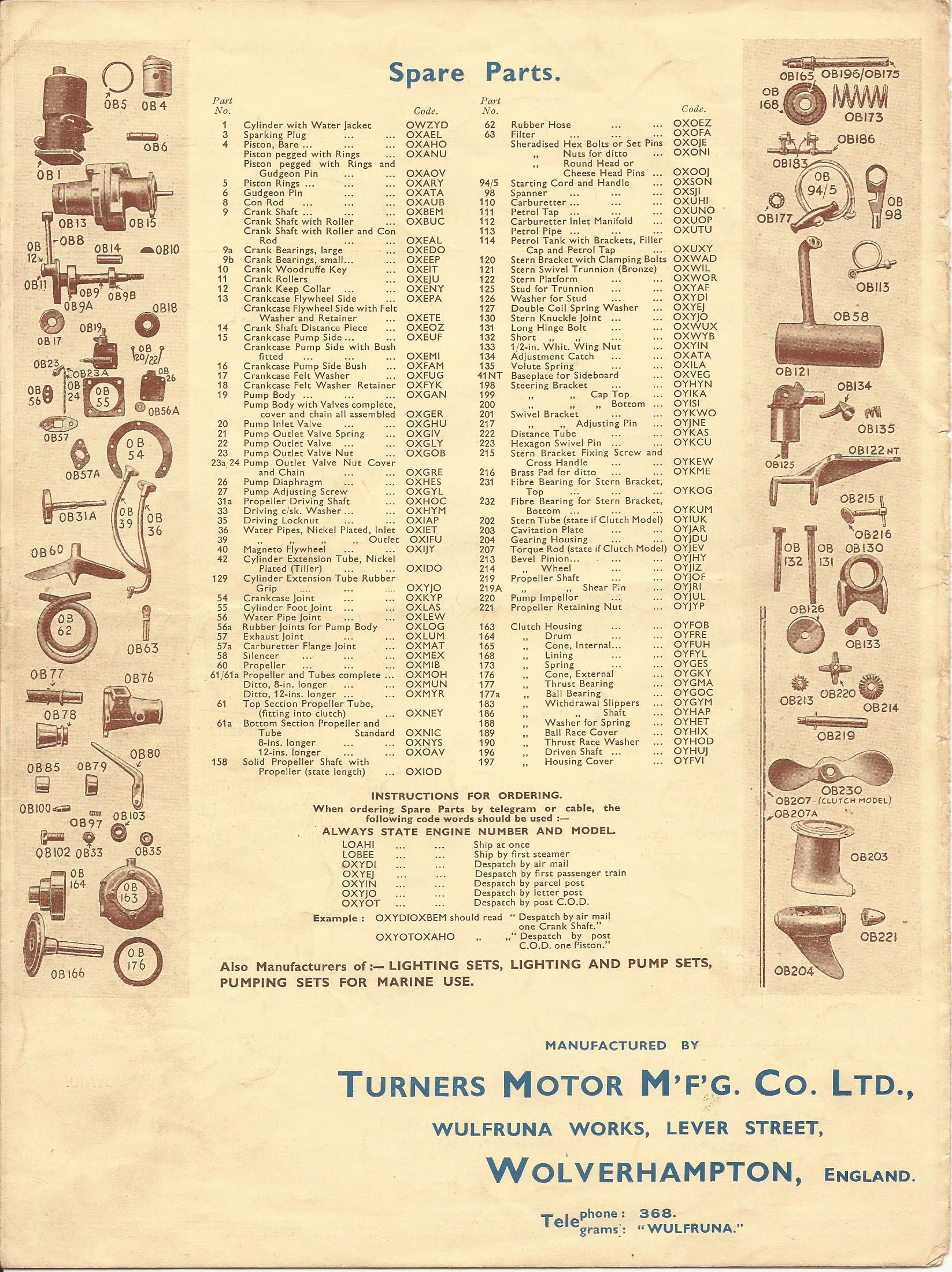

TURNER BRAY OUTBOARD ENGINE

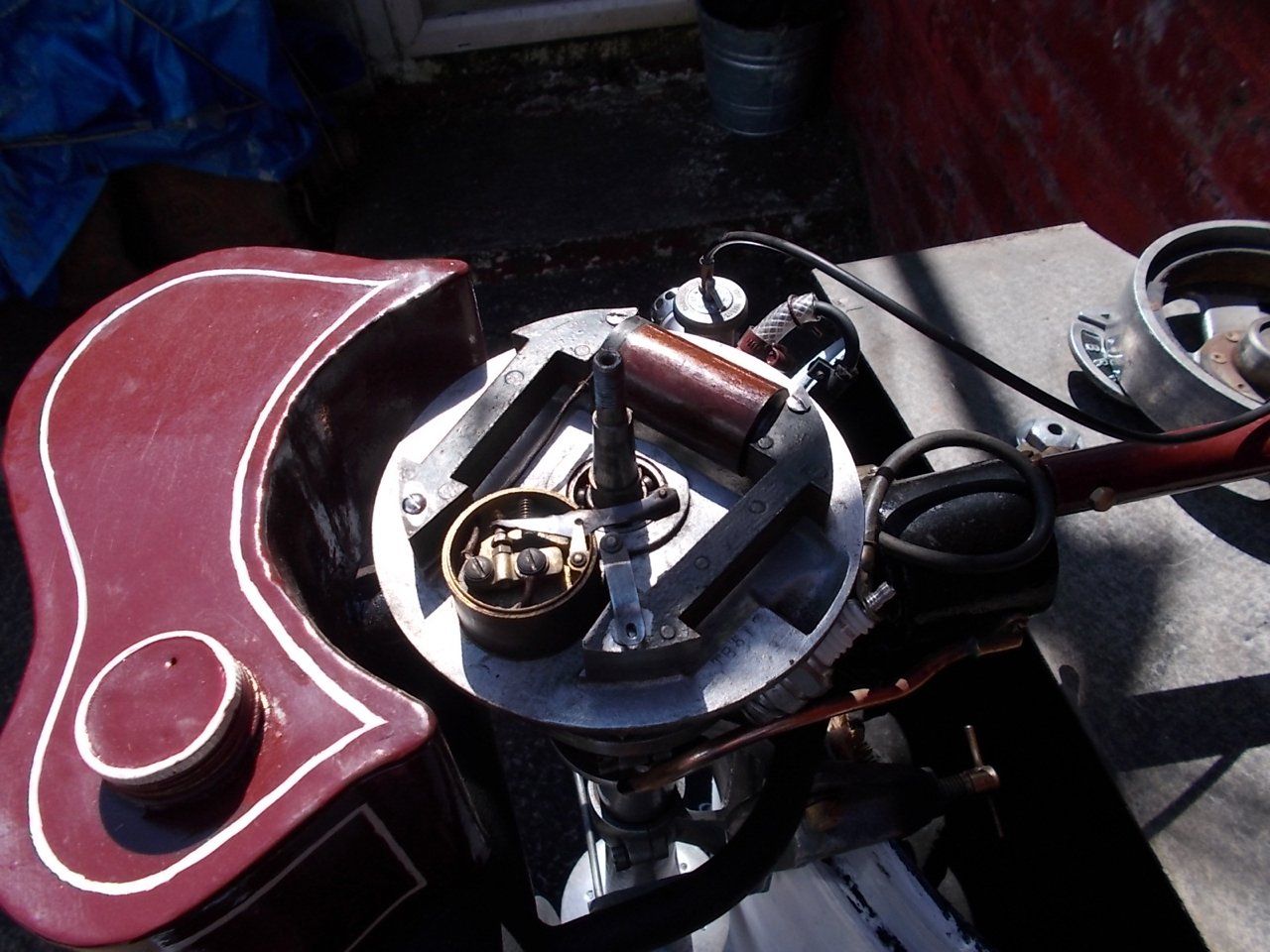

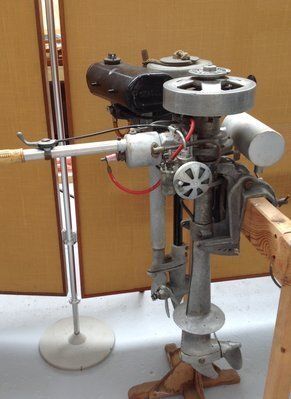

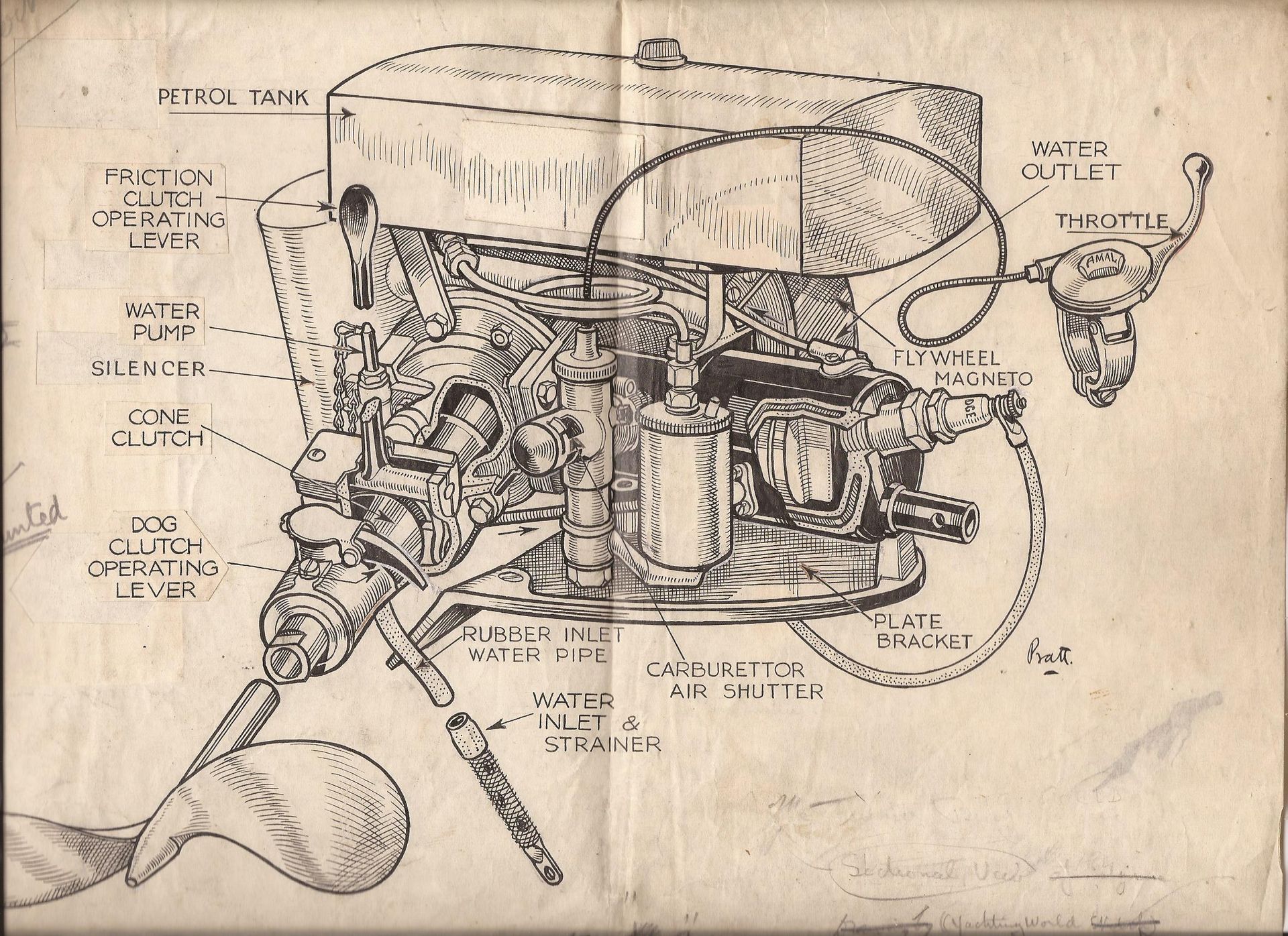

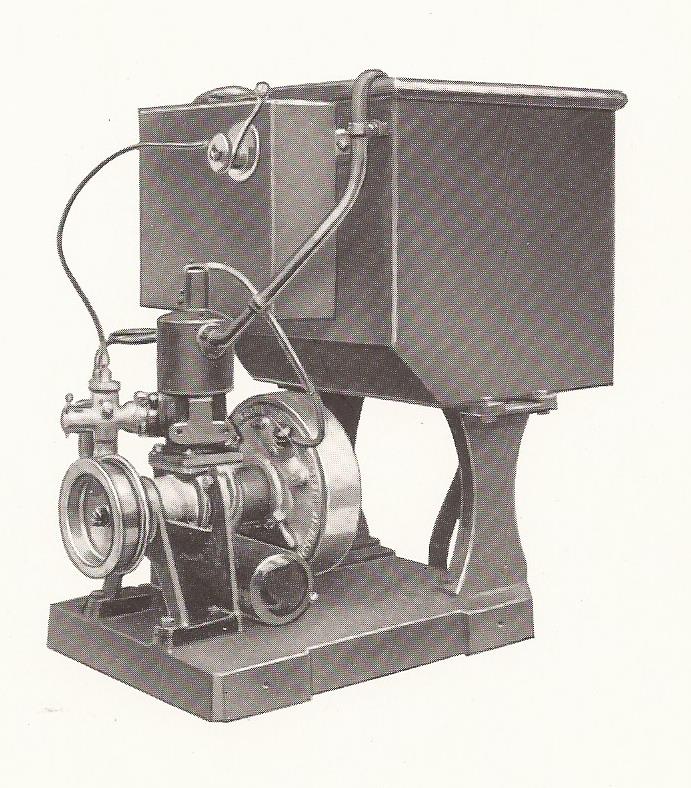

The two pictures below are of a Turner Bray outboard engine:-

Very recently I have become aware of another Turner Bray engine as shown in the two following pictures and I can report that I was the owner of this engine but it was damaged in the steading fire and is now in the hands of another who is merging parts of it with another engine:-

More recently another Turner-Bray engine has turned up and the owner has got it up and running as per the Youtube link immediately below.

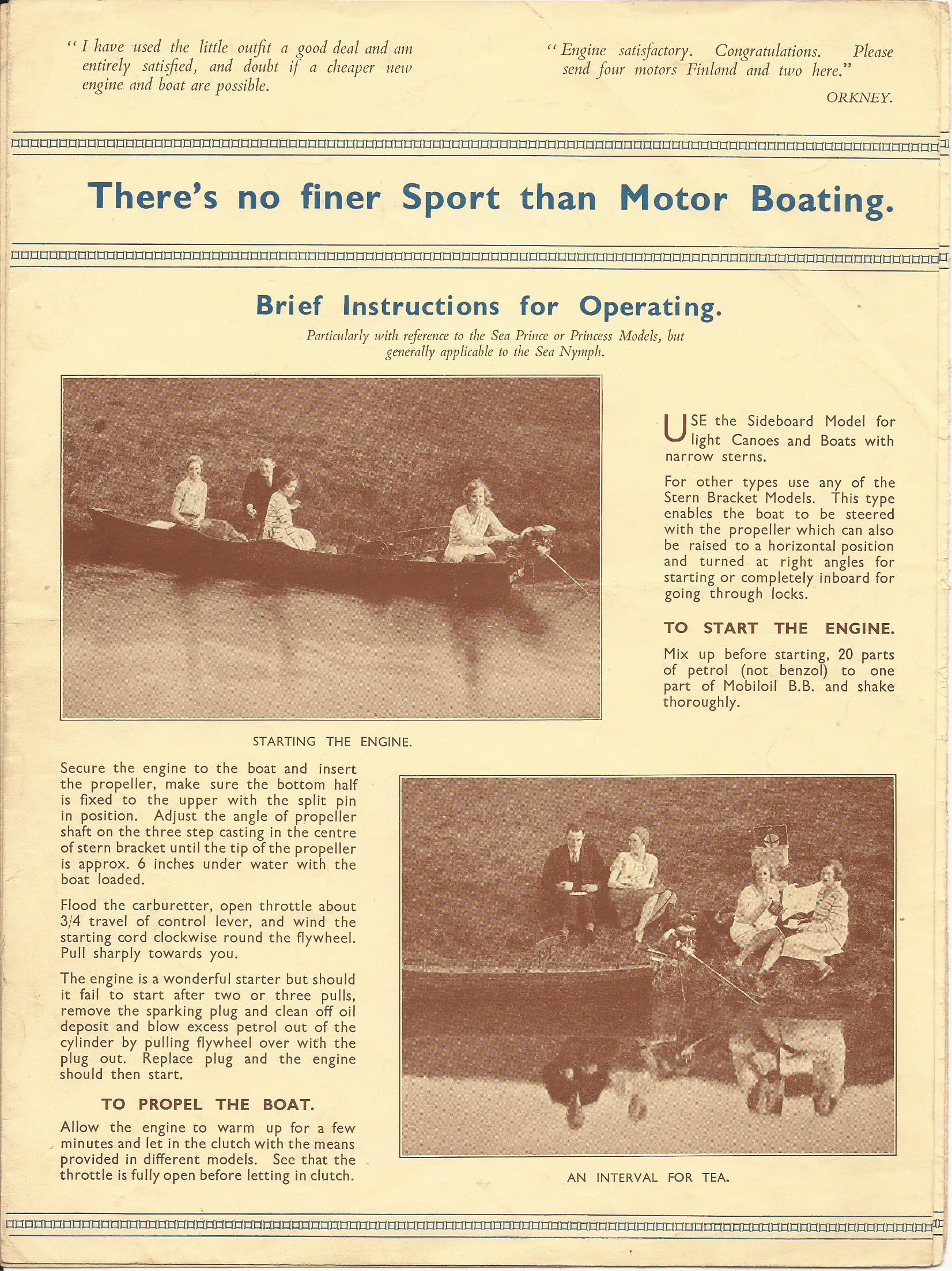

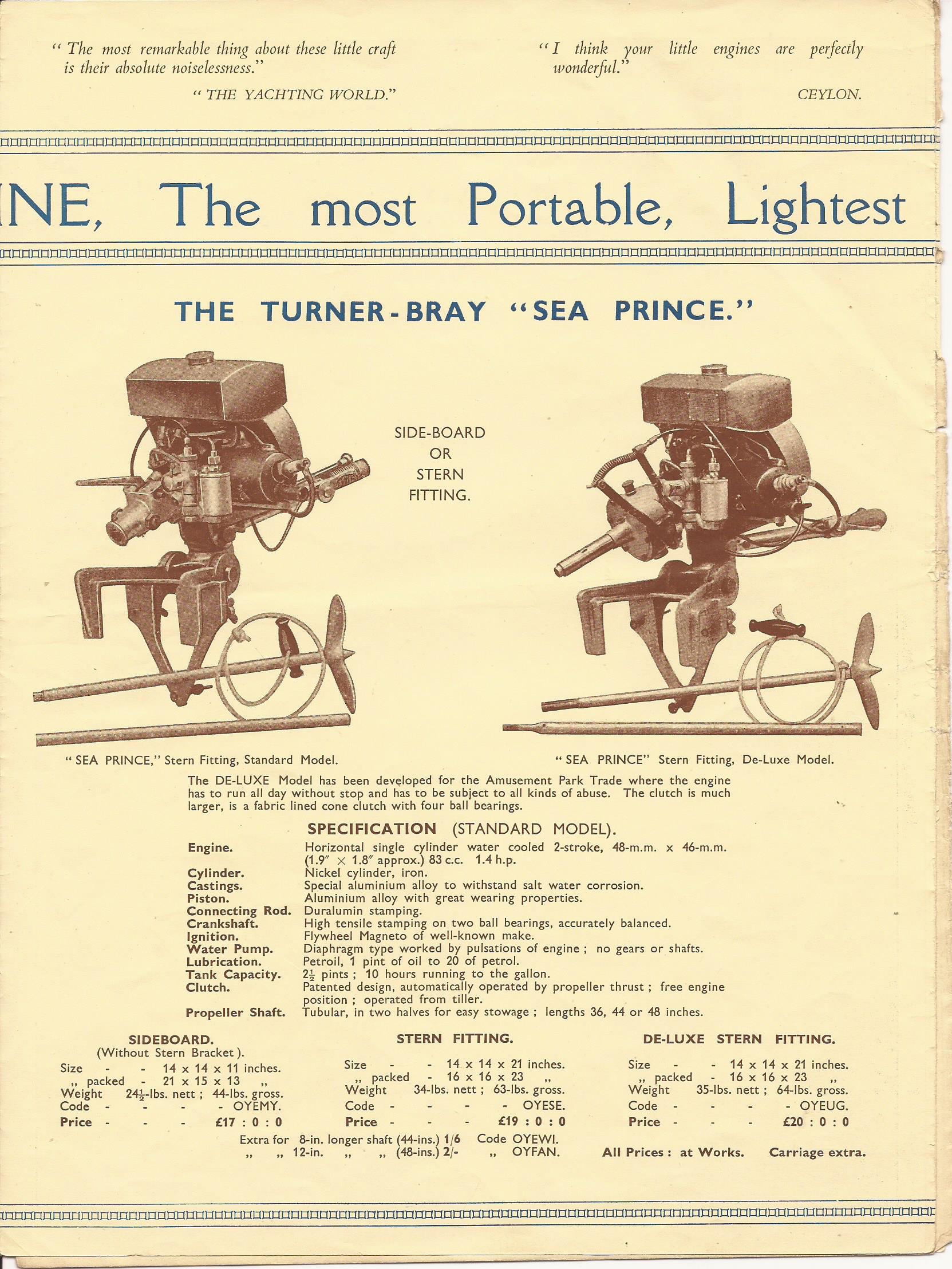

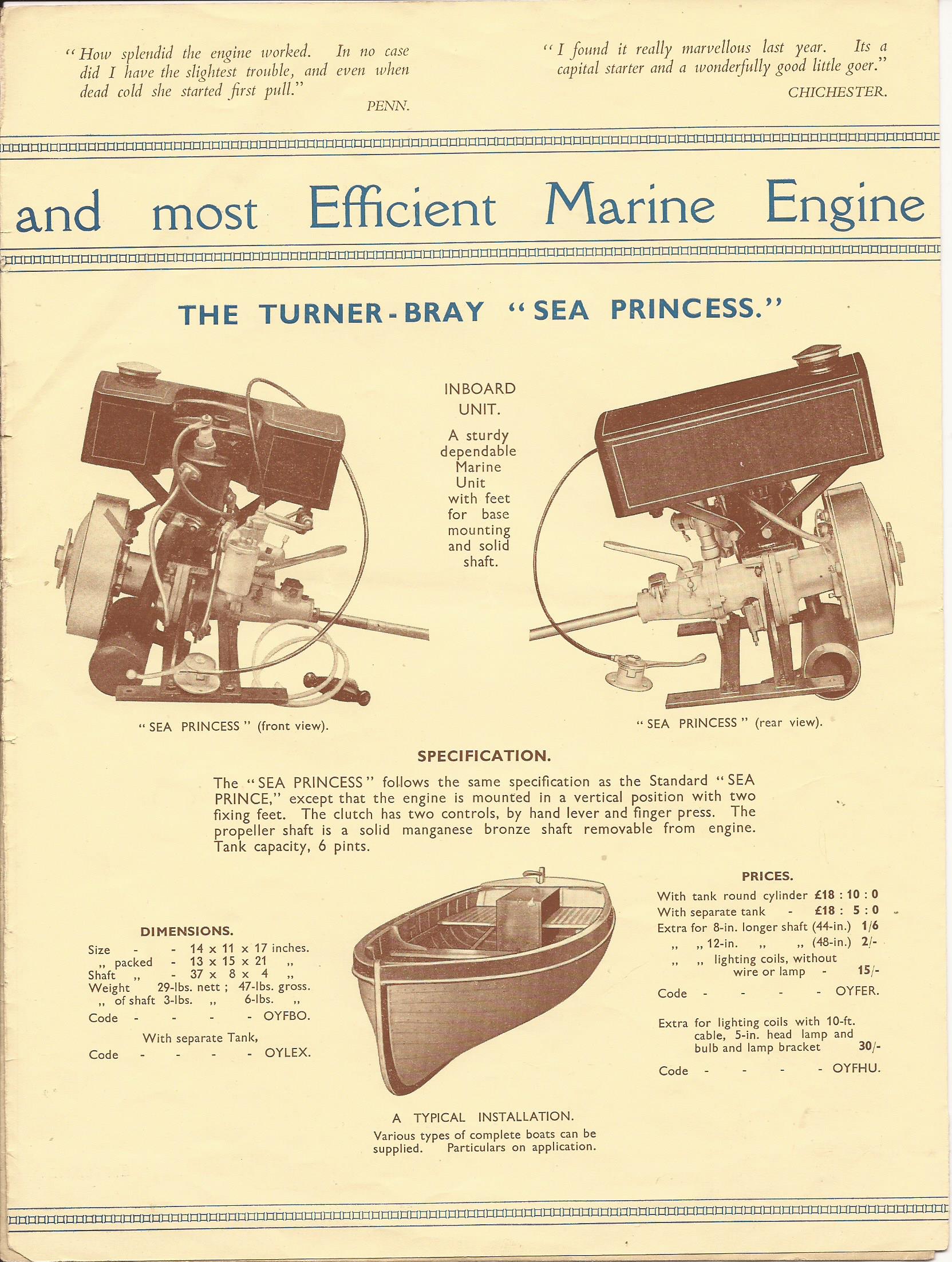

I also have a PDF document relating to these engines which is now shown in .jpg format below.

Today (2nd June 2018) my younger son and I decided to have a look at getting the above engine running as it has been with us for over a year lying unloved and neglected on a shelf.

As shown in the above picture with its former owner we rigged the engine in a wheelie bin:-

This last picture is actually of another Turner Bray engine as shown in the YouTube video below. We need to lift the flywheel and have a look see at the points as the next line of attack but we ran out of time today. I have read on the British Seagulls Engine Forum that these magneto's are known as 'Coolie Hat' Villiers magneto's (not quite sure of the political correctness of such a reference nowadays!).

30+ years of experience of Land-Rover SU fuel pumps and points tells me that this is the most likely cause of there being no spark here. Hopefully we'll get another look on Monday.

Whilst doing a spot of surfing on Turner Bray engines I find there still isn't a great deal to be found but one new link is an article I found in an American publication called Motor Boating of February 1931:-

SMALLEST OUTBOARD MOTOR

The smallest and lightest outboard motor in the world is the Turner-Bray, an English motor designed for propelling small rowing boats and yacht tenders. It develops 1 ¼ h.p. at 1800 r.p.m. on a bore of 1.8 inches and a stroke of 1.9. It weighs complete only 17lbs and is said to be able to drive a small boat at 6 m.p.h. on less than a pint of gasoline per hour.

Another link took me to the Motor Sport magazine of November 1931:-

The Wearside Boatbuilding Co. had on their stand an lift (clearly a scanned typo), dinghy powered with the inboard edition of the Turner Bray engine. The boat is quite light and can be handled easily by two persons, yet in spite of this, the strength of the boat has not suffered. The price is £52 10s.

Yet another link took me to a book Sea Fishing for Amateurs:-

A still lighter engine of British make is the 1.4 h.p. Turner-Bray (Arthur Bray Ltd., 114 Baker Street, LONDON. W1.) . In spite of its small size, this engine is claimed to propel a 12ft dinghy at 6 m.ph.

The following photo's are courtesy of a guy off the Saving Old Seagulls forum of an engine located in a museum in Cowes on the Isle of Wight:-

The following is a Turner-Bray brochure:-

Various other Turner Bray pictures:-

As I re-process this site in January 2023 I can't recall the details as to who/ what/ where I have a number of pictures of this engine:-

Turner Machine Tools

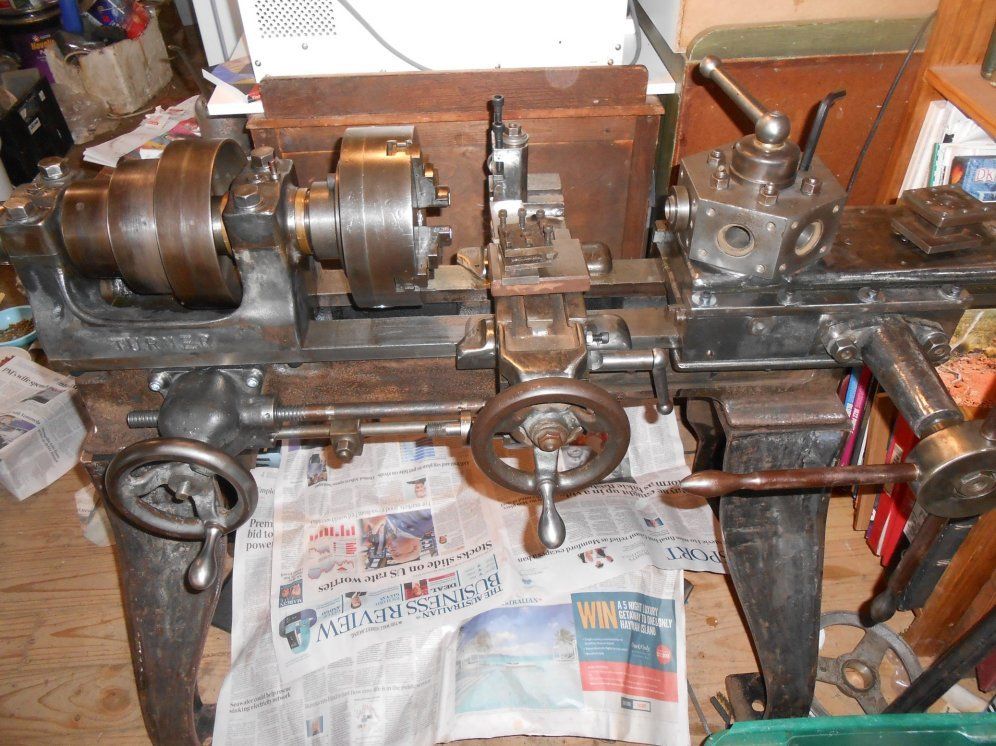

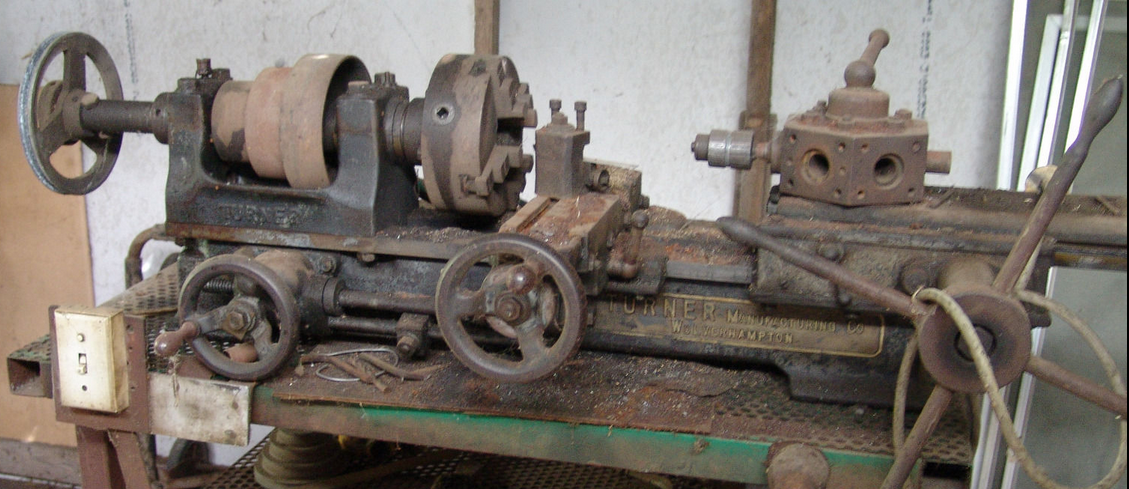

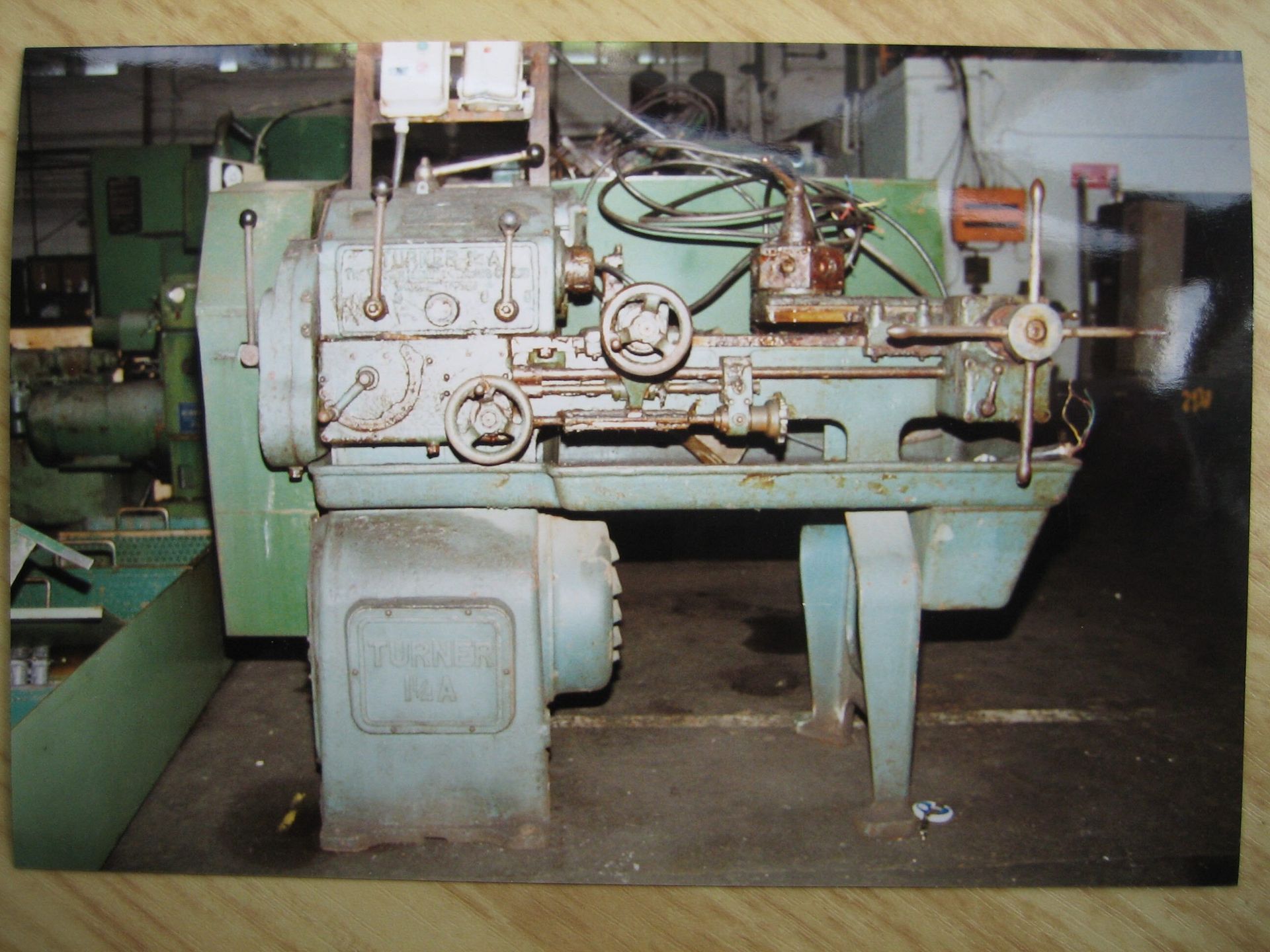

I received the first picture back of a genuine Turner lathe back in in April 2017. The owner advises it came off a farm some 76 miles from Victoria (Australia) and that it is fitted with a 7 1/2" Cushman Chuck Co chuck.

After advising Larry Hopkins that this lathe had been 'discovered' he provided the following information and photographs:-

What I have found is some photos of the Turner machine tools that were at the TMC Fordhouses factory at the time it was being cleared out. You are welcome to post them on the web site. Three Tool & Cutter Grinding machines and one Turner Lathe were sent to the Black Country Living Museum for safe keeping.

The Turner lathes were a capstan lathe very similair to the Herbert 1A. The one at Turners was a 1 1/4 which, I think refers to the bore of the spindle. The designation as a turret lathe is American parlance whereas the capstan name was used in the UK because of the arrangement to index the tool holders.

Production of the lathes started during the 1914 to 1918 war and continued in small numbers into the 1930's. During WW2 Turners production was concentrated on aircraft undercarriage and military recovery winches. Jowett at Idle, Bradford made some 250 "Turner" lathes during WW2.

Turners Agricultural Involvement

Turners are perhaps best known for the “Yeoman of England” tractor {featured above} which utilised the 4V95 engine and was offered with a range of “approved” implements such as ploughs (made by Adrolic), tool bar equipment & cultivators (made by Leverton) and a cab (made by Scottish Aviation).

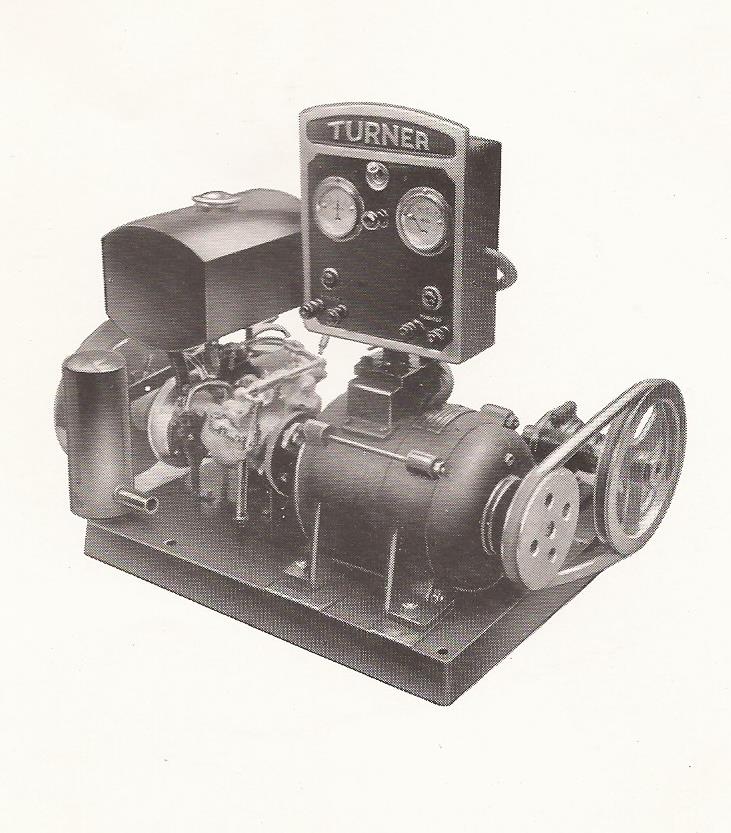

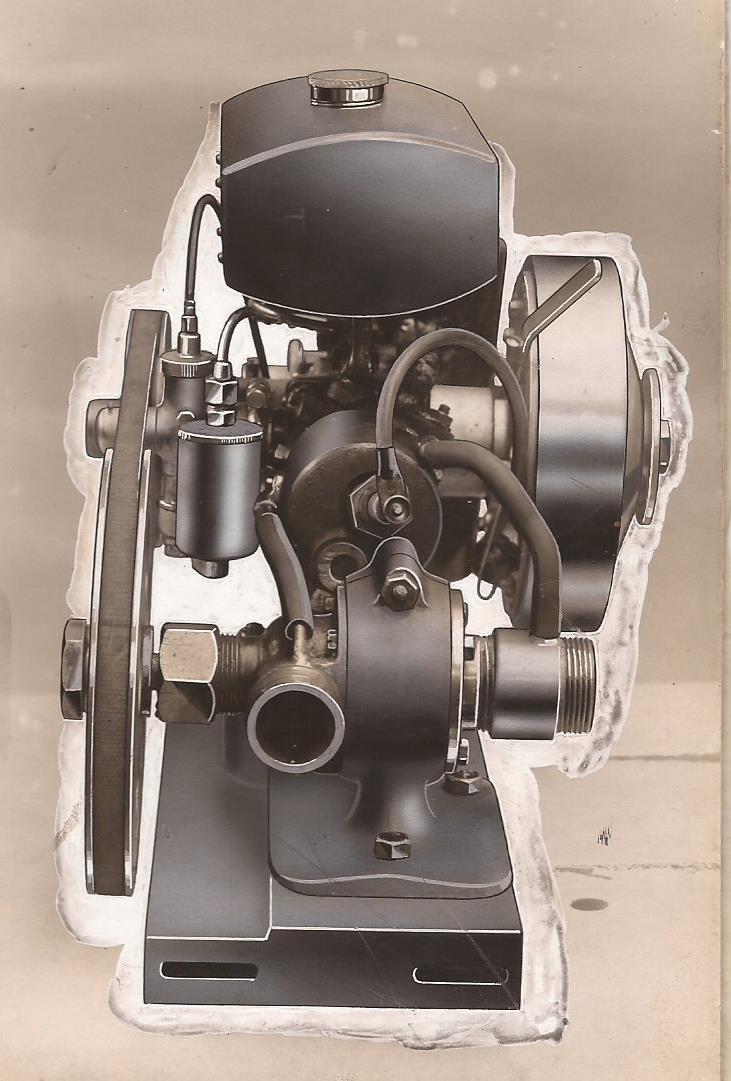

The V95 engines came in single, V twin and V4 sizes and were used for all of the typical stationary engine applications such as simple belt pulley drive for saw benches etc, as electrical generating sets and as pumping sets.

The 4V95 engine was also offered in such as the crawler tractors made by F H Loyd of Camberwell, Surrey.

Loyd Crawlers

F H Loyd of Camberwell Surrey were major producers of utility (Bren Gun) carriers during WW2. After the war they marketed a crawler tractor with the same driveline as the carrier powered by the Ford “flat head” V8 petrol engine.

The Turner 4V95 engine was offered as an alternative for this carrier based machine. There were problems with track wear and brakes and the machine was considered to be too fast for agricultural work.

An upgrade to the machine was called the “Loyd Dragon” and offered with the Turner 4V95 or a Dorman engine as options.

Fordson E1AN Major

After the “Yeoman of England” tractor ceased production Turners gained major sub contract work for FORD tractor. For the Fordson E1AN Major range of tractors they supplied: -

COMPLETE HYDRAULIC ASSEMBLIES

TOP LINKS

BELT PULLEY ASSEMBLIES

Ford 6X

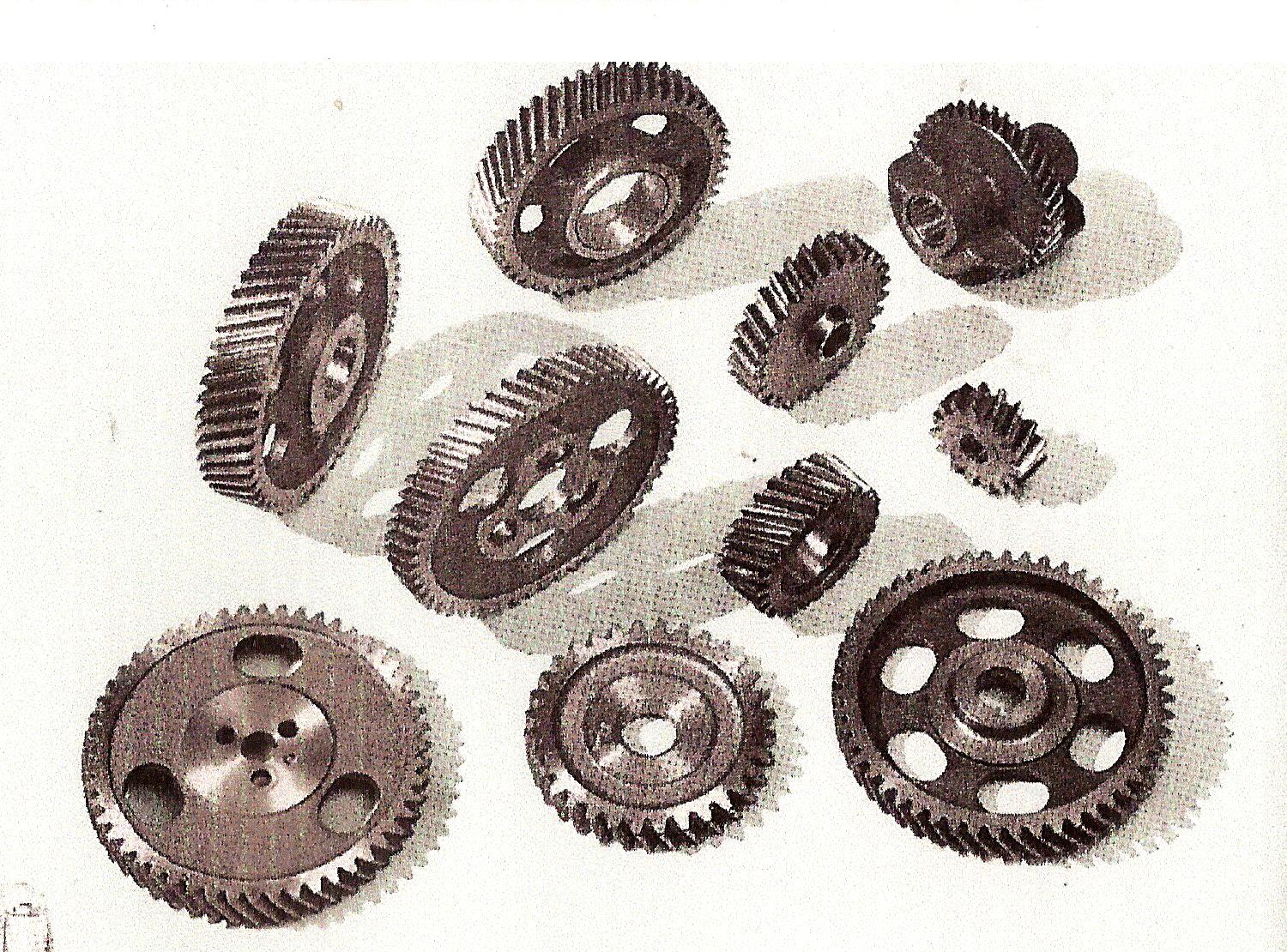

When the 6X range of tractors were introduced Turners supplied all of the front end timing gears including the balance weight gears for the 4 cylinder engines.

These were shown in a typical publicity brochure for Turners.

International Harvester & Case

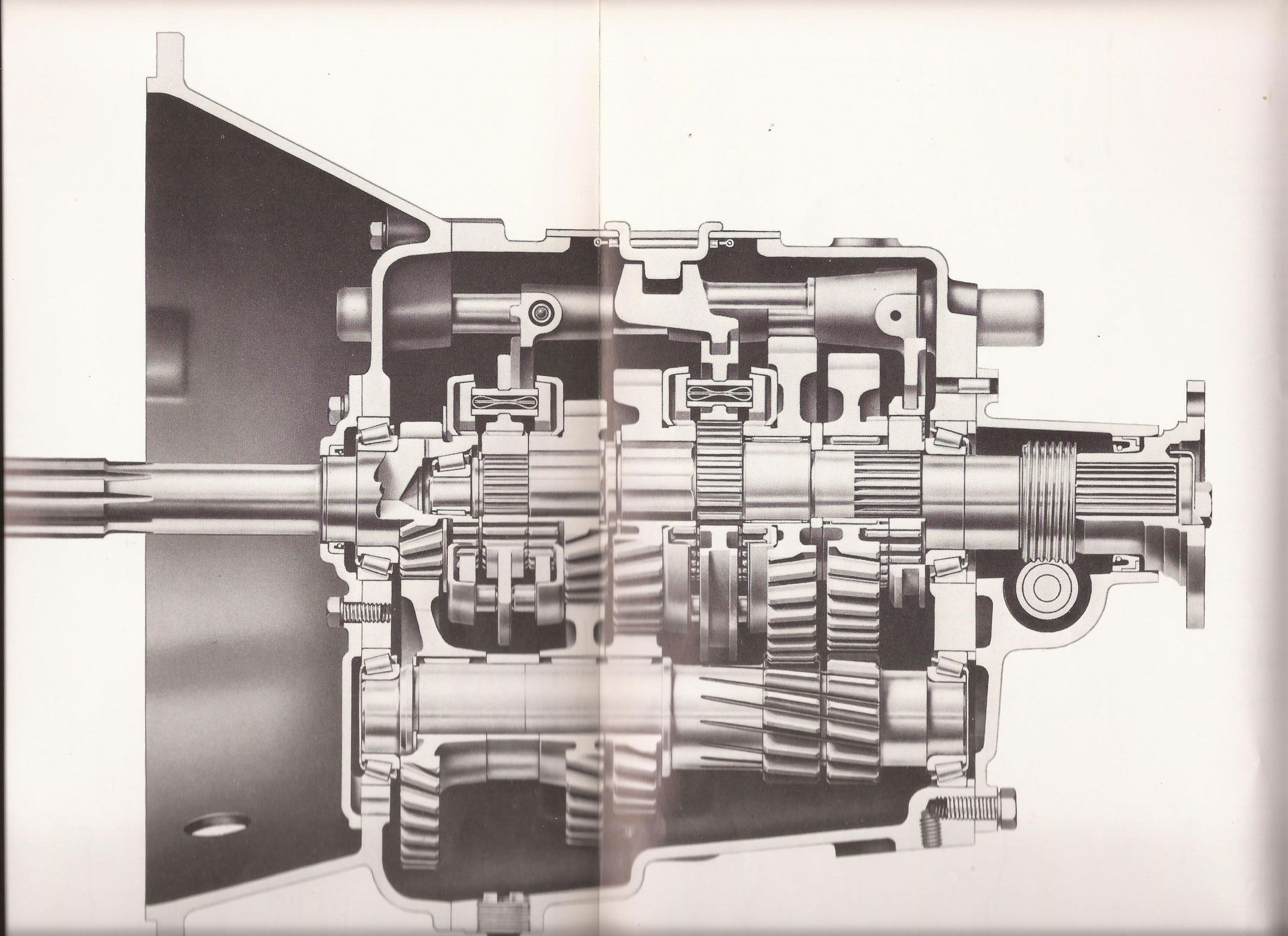

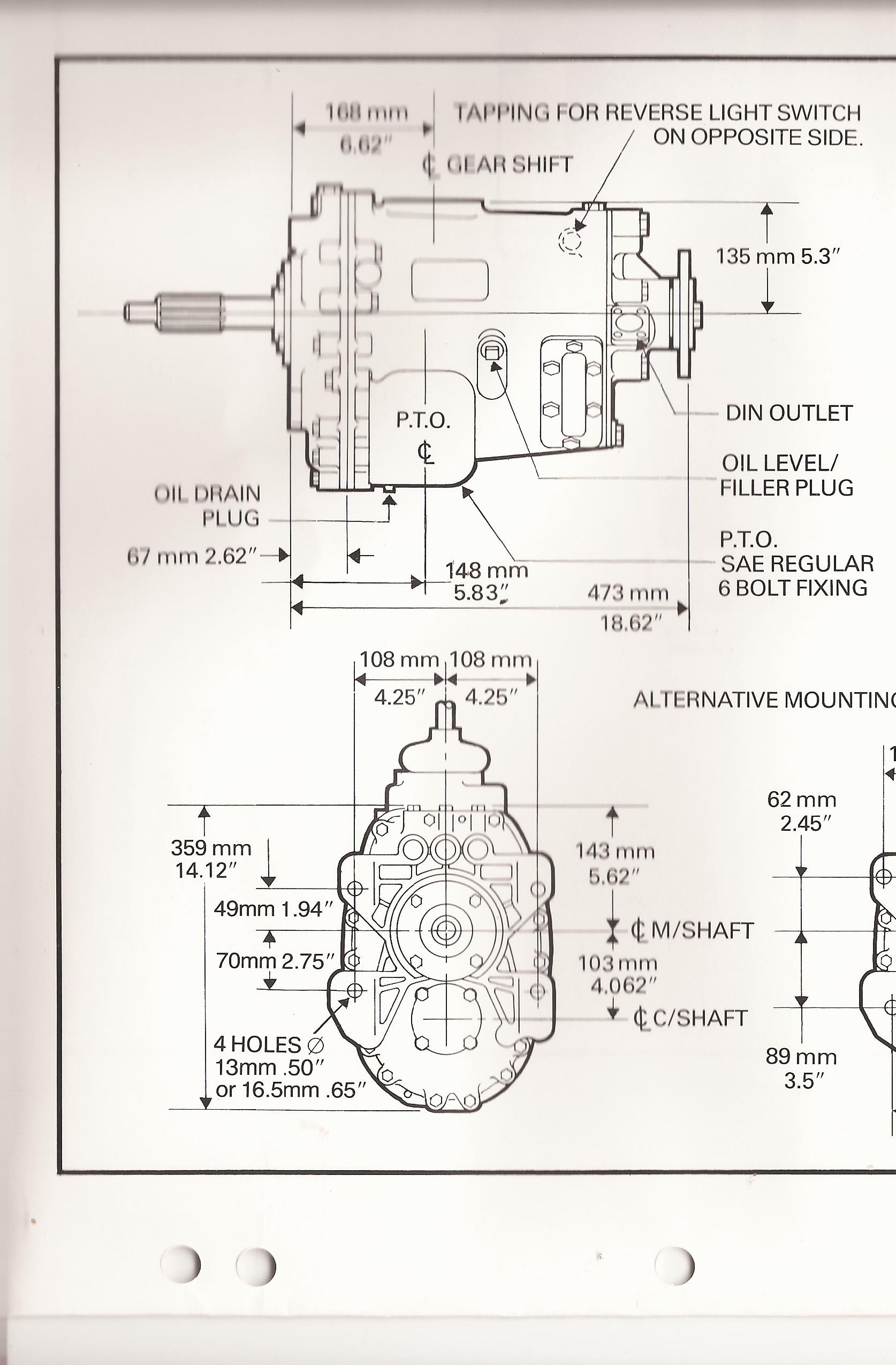

In 1968 Turners developed a new gearbox for the 7.5 ton Leyland Terrier vehicle in the Redline range of trucks produced at Bathgate.

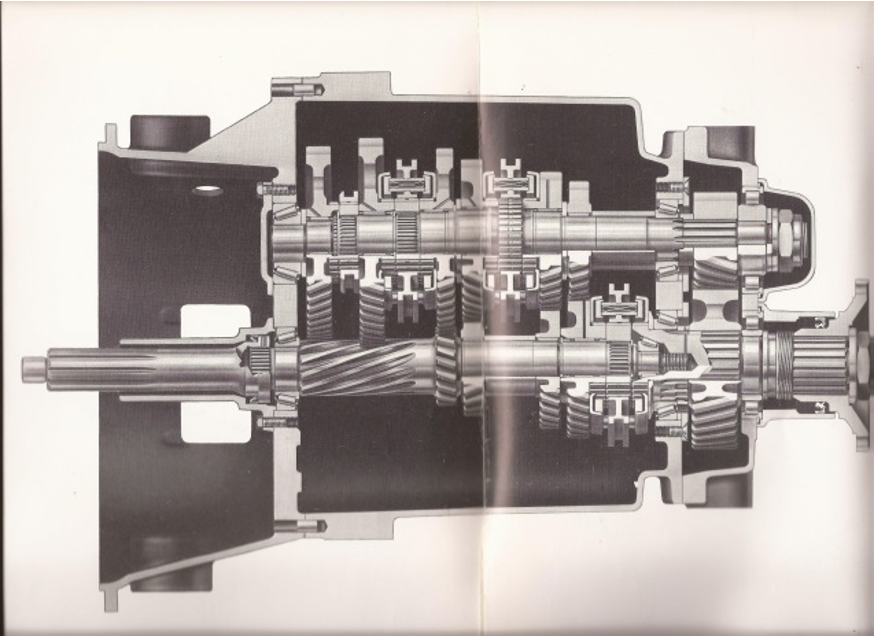

The gearbox had a number of innovations such as all the shaft support bearings being taper roller type and for the synchroniser assemblies the “cup” of the cone clutch was made as a separate steel pressing. The gearbox was the T4-200.

A five speed version of the gearbox was also done and this developed on into the T5-250 and then the T5-290 gearbox with the main customer being Leyland trucks, the “Roadrunner” and then the 45 series.

When the gearbox of the International harvester range of tractors was revised to fit synchronisers the unit chosen was a version of that from the T4-200 gearbox. The main difference being that a finer pitch spline was used for the dog teeth in the tractor gearbox.

The turner Synchronisers tractors were introduced in 1972 on the 454, 475, 574 and 674 models.

The use of Turner synchroniser continued through the introduction of the Case 85 and 95 series up until 1996 when, as part of the MX05 upgrade, the “ZF” style or “strut” type synchroniser was used.

Leyland Synchro

When the Leyland tractors gearbox was revised to include synchroniser units the engineers at Bathgate contacted Turners.

In the 1970’s Turners had been developing a whole new range of truck gearboxes called the “M Series”. These were 5 and six speed units with capacities of 350 476 and 650 lbsft torque. These had a number of innovative features such as the primary reduction ratio being achieved using a pair of “bull gears” located at the rear of the gearbox. This allowed the use of very narrow face width gears and for the synchronisers to be put on the layshaft.

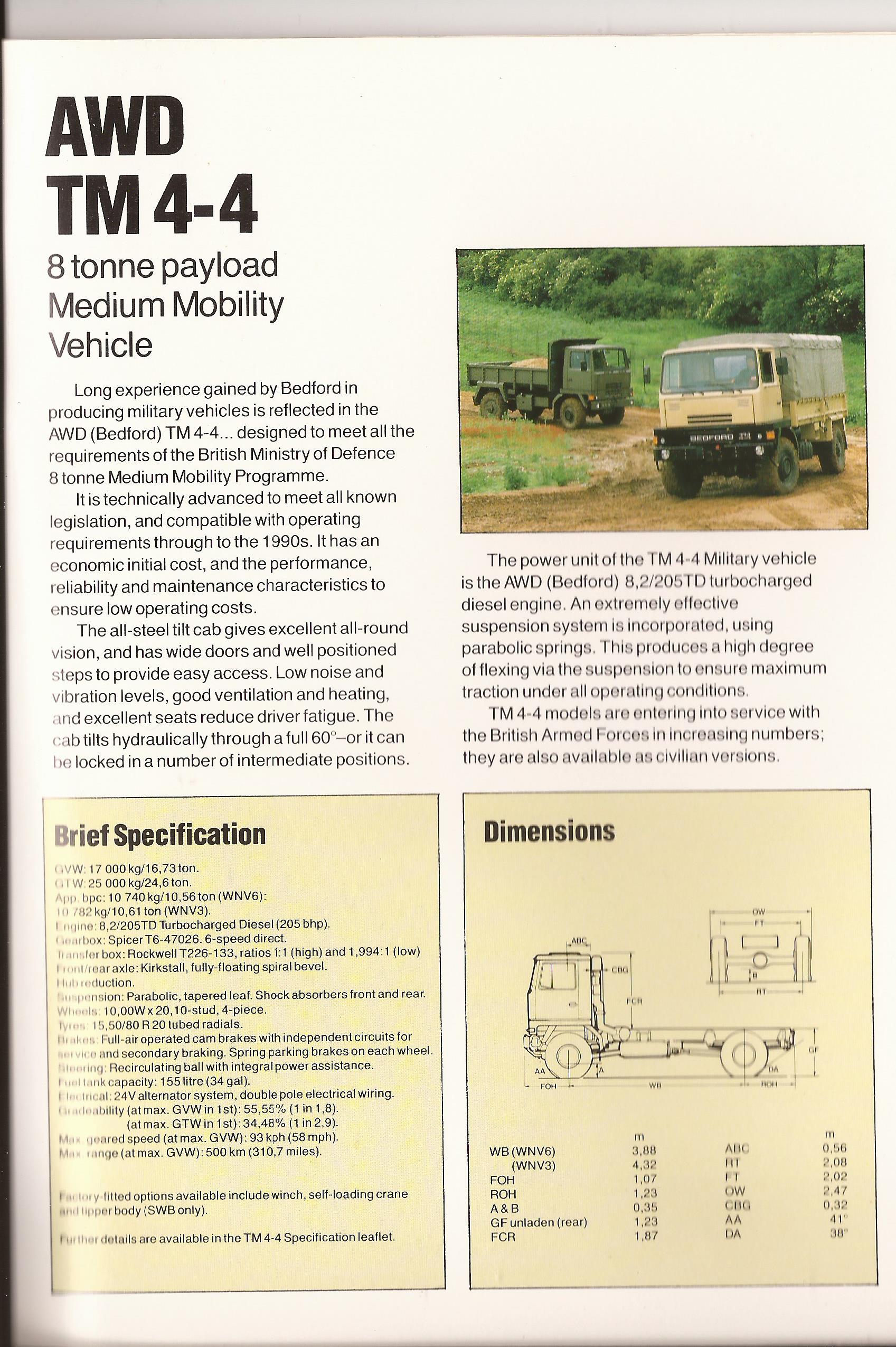

For a variety of reasons only the M6-476 transmission was put in to limited production for the Bedford Military vehicle based on the tilt cab TM range.

The synchroniser unit selected for the Leyland tractors was taken from the M6-350 transmission.

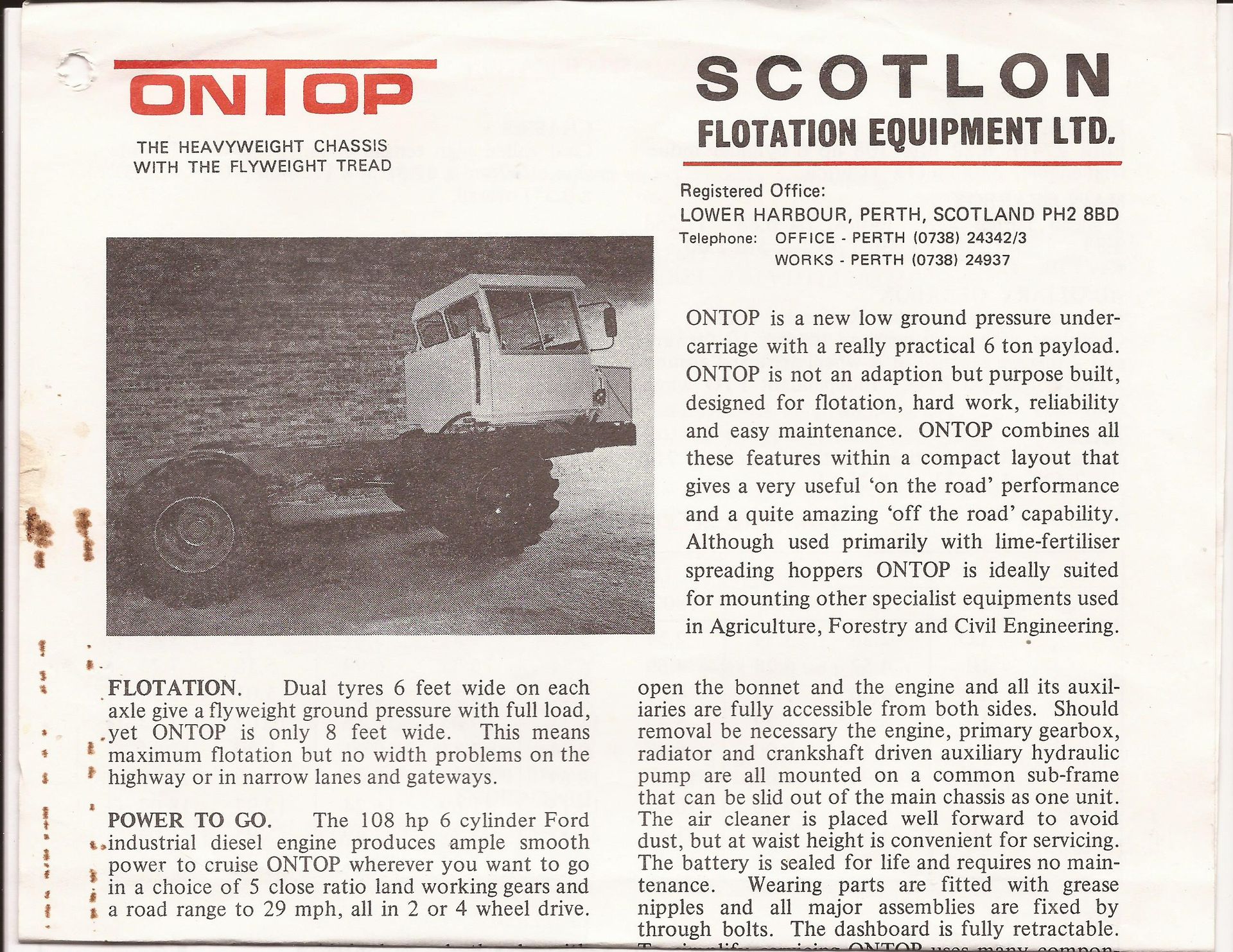

Scotlon Flotation

Agricultural Lime and Fertilizer spreader designed by Mr Gillon.

The company name was later changed to OnTop Tractors.

The early machines used a Ford industrial engine with a Turner T5-300 Ford truck gearbox.

Have any of these early machines survived?

The driveline on the later machines was changed to be Cummins engines with Eaton gearboxes.

Clayton Buggy

Lucassen Young, a John Deere dealership, developed a sprayer machine using a JD engine.

This was coupled to the T5-290 gearbox from the Leyland Roadrunner vehicle.

Drainage machines

Turner truck gearboxes were used in the driveline of various drainage or ditch digging machines to vary the speed of the digging chain.

A T5-300 box was used with the Ford engine on the small machines made by Bruff Engineering. At the suggestion of Turners the cable linkage from the drivers platform to the gearbox was upgraded from the standard “ Morse” type to the linear ball bearing “Bowden-flex” type.

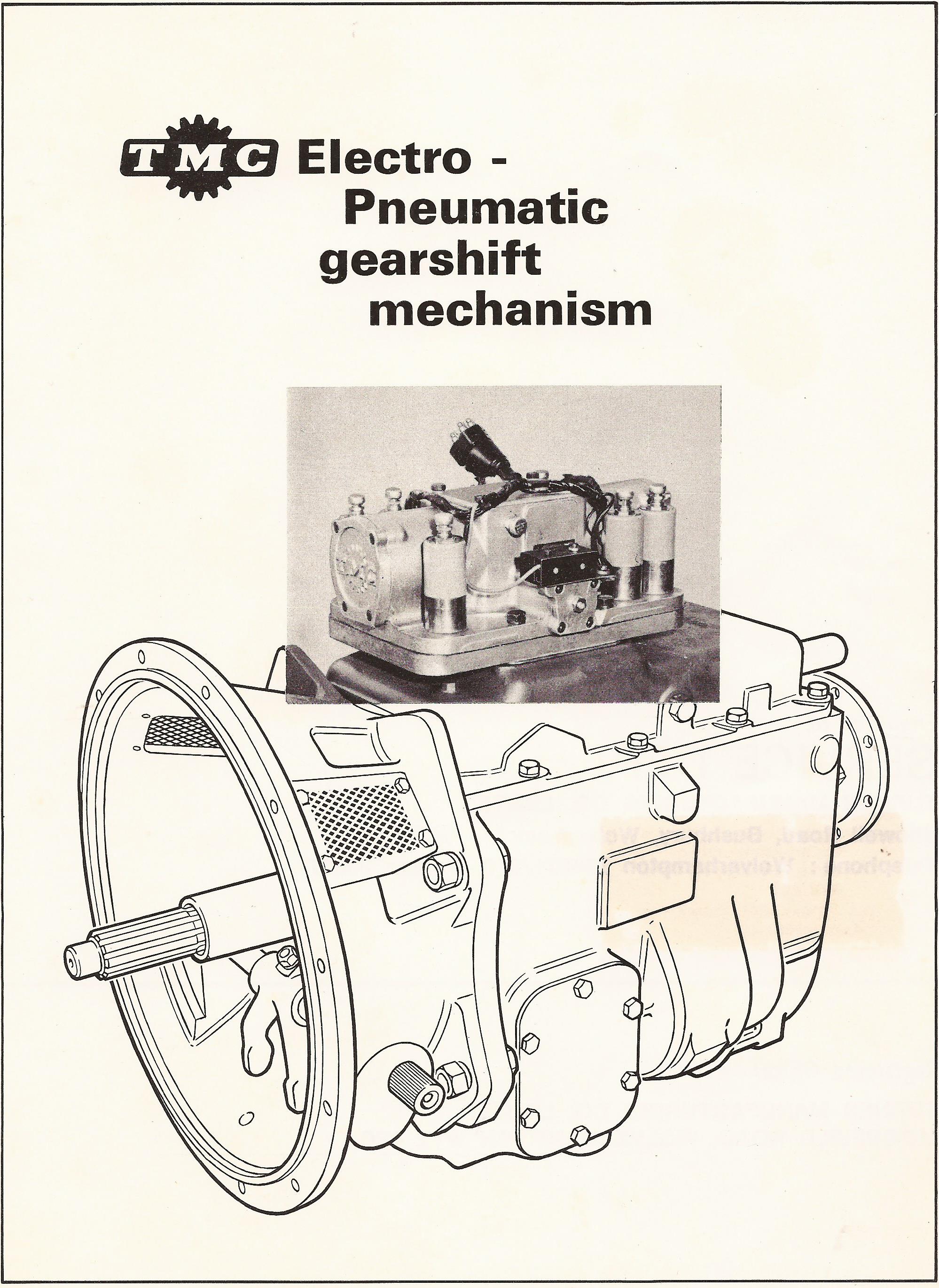

A T5-400 was used on the Vandenede machines fitted with the Cummins Vale V8 engine. As the gearbox was some distance from the operator the gearbox was fitted with an “airshift” control unit. This basically used a simple arrangement of air cylinders to move the gear selectors within the gearbox. It had been evaluated with reasonable functional success on coaches including some in service with Don Everalls, the Ford dealer and travel operator in Wolverhampton. The idea was not taken up by the vehicle manufactures.

It was not very successful on the Vandende machines. The unit would attempt to “force” the synchroniser to activate even when the operating conditions were against it. In a road going vehicle the synchroniser cone clutch works because the output of the gearbox is essentially being driven at a constant speed by the rear wheels. When a digging chain has come to a complete stop the synchroniser becomes simply a dog clutch. In fact the gearbox was modified to be a simple dog engagement box rather than being synchronised. However, it would be interesting to know if any of these airshift units have survived even if they have been removed from the machine.

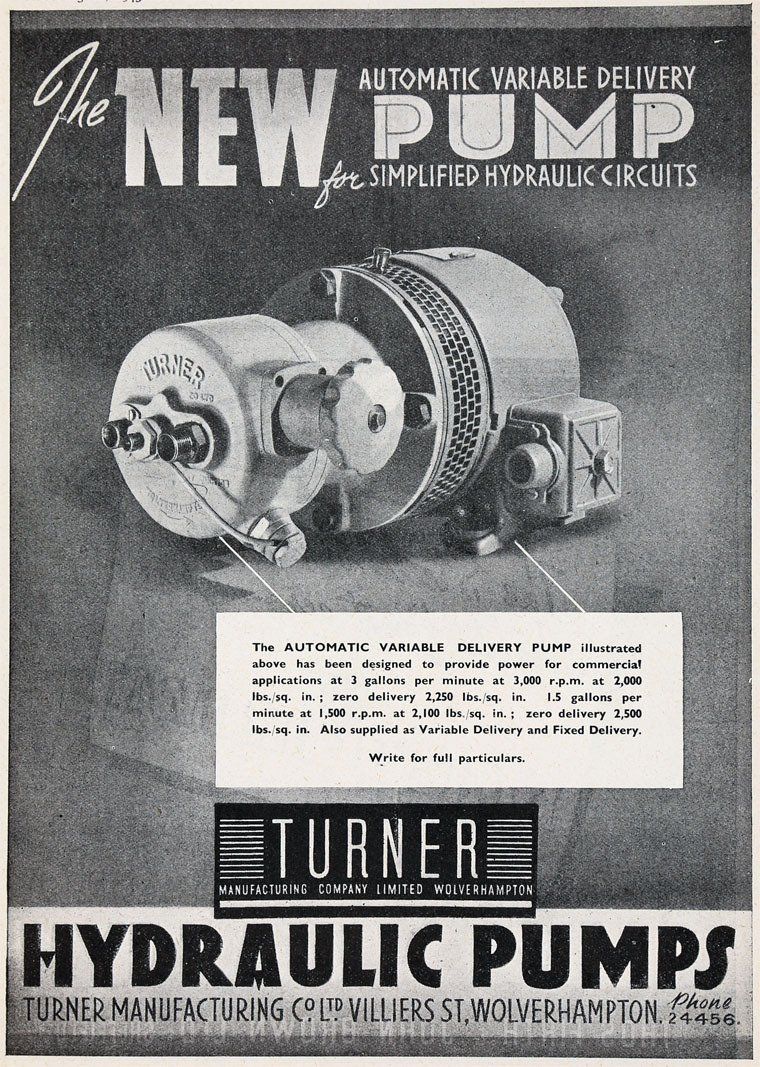

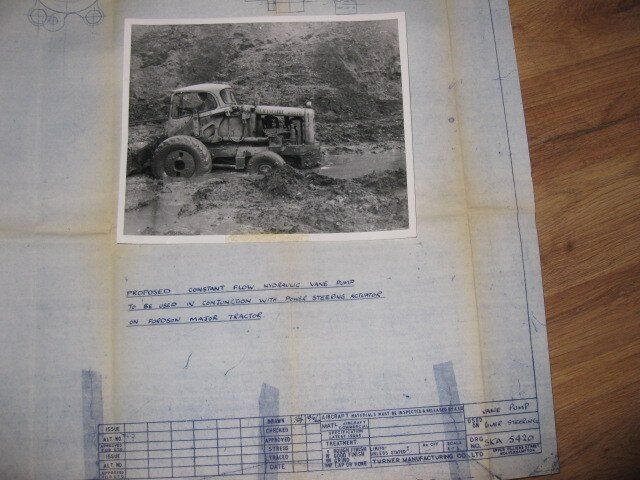

Power Steering Kit

Done by the Turner subsidiary H&P.

Used their own design of hydraulic pump with a “Leduc” steering ram.

It is thought that these were offered for Fordson tractors but the only known application was as shown on a Chaseside loader shovel – which is based on a Ford skid unit.

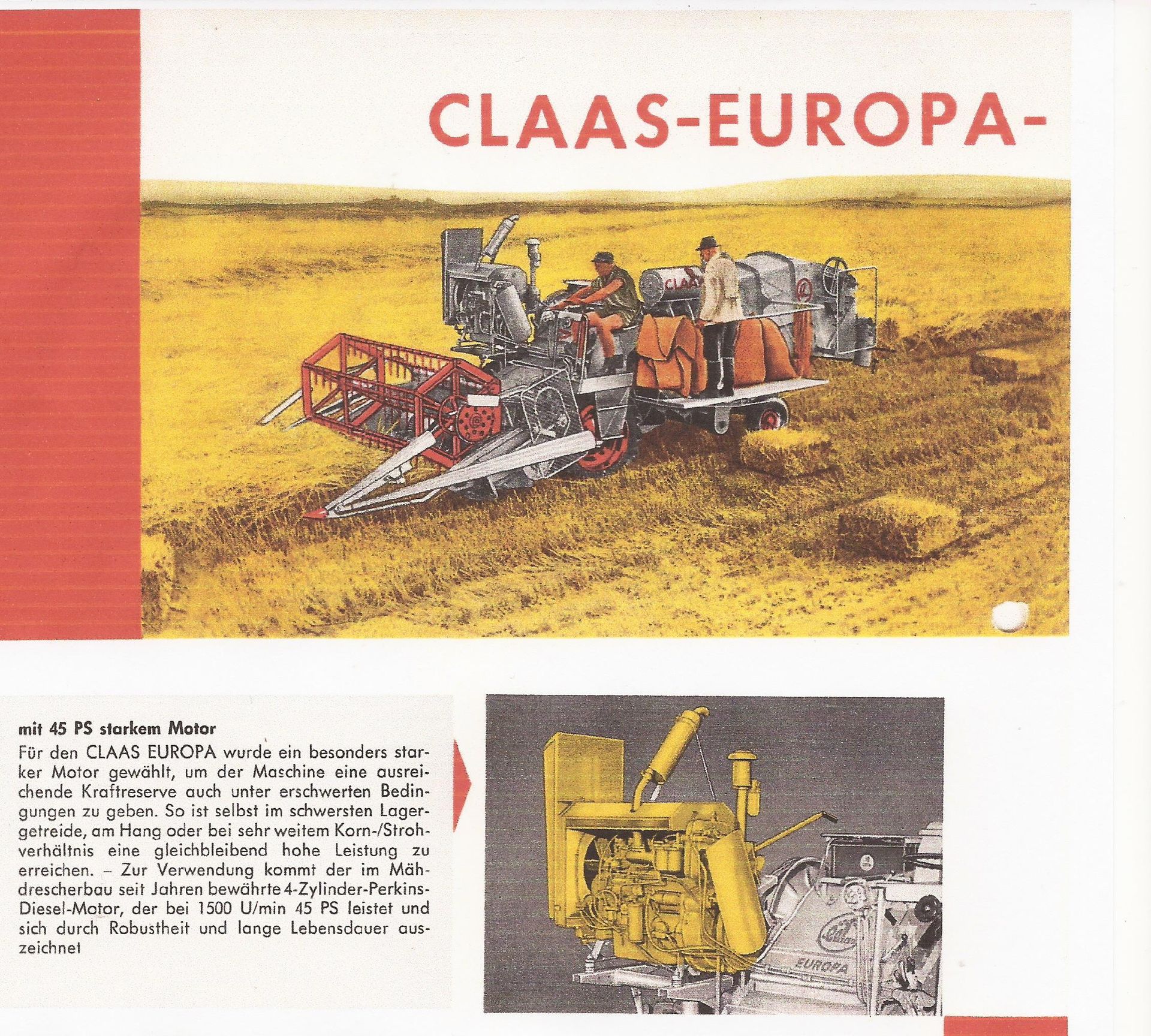

Claas Combines

The Turner-List two stroke blown diesel engines were offered as a repower unit for the Land Rover. After that engine ceased production in 1958 the machine tools were utilised to supply “kits of major parts” to the initial production of the Perkins 4.99 engine. Once production volumes built up the work was taken in house at Peterborough.

A typical early agricultural application of the Perkins 4.99 would be the Claas Europa combines of 1958 and 1959 and the Claas Columbus combine of 1959. These machines were also offered with a petrol engine or a Mercedes diesel but it is the Perkins engine option that has the Turner interest.

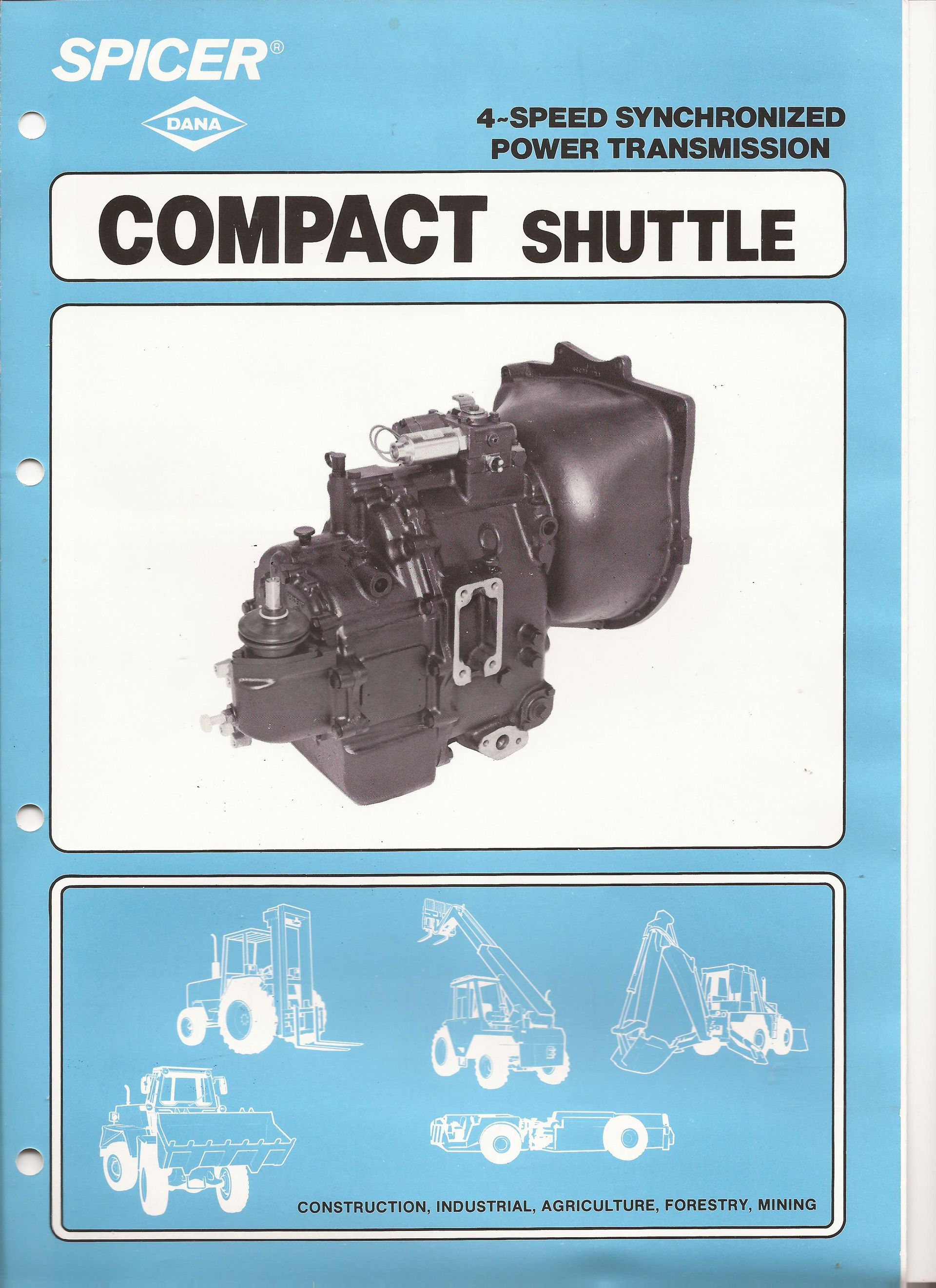

Tele-handlers

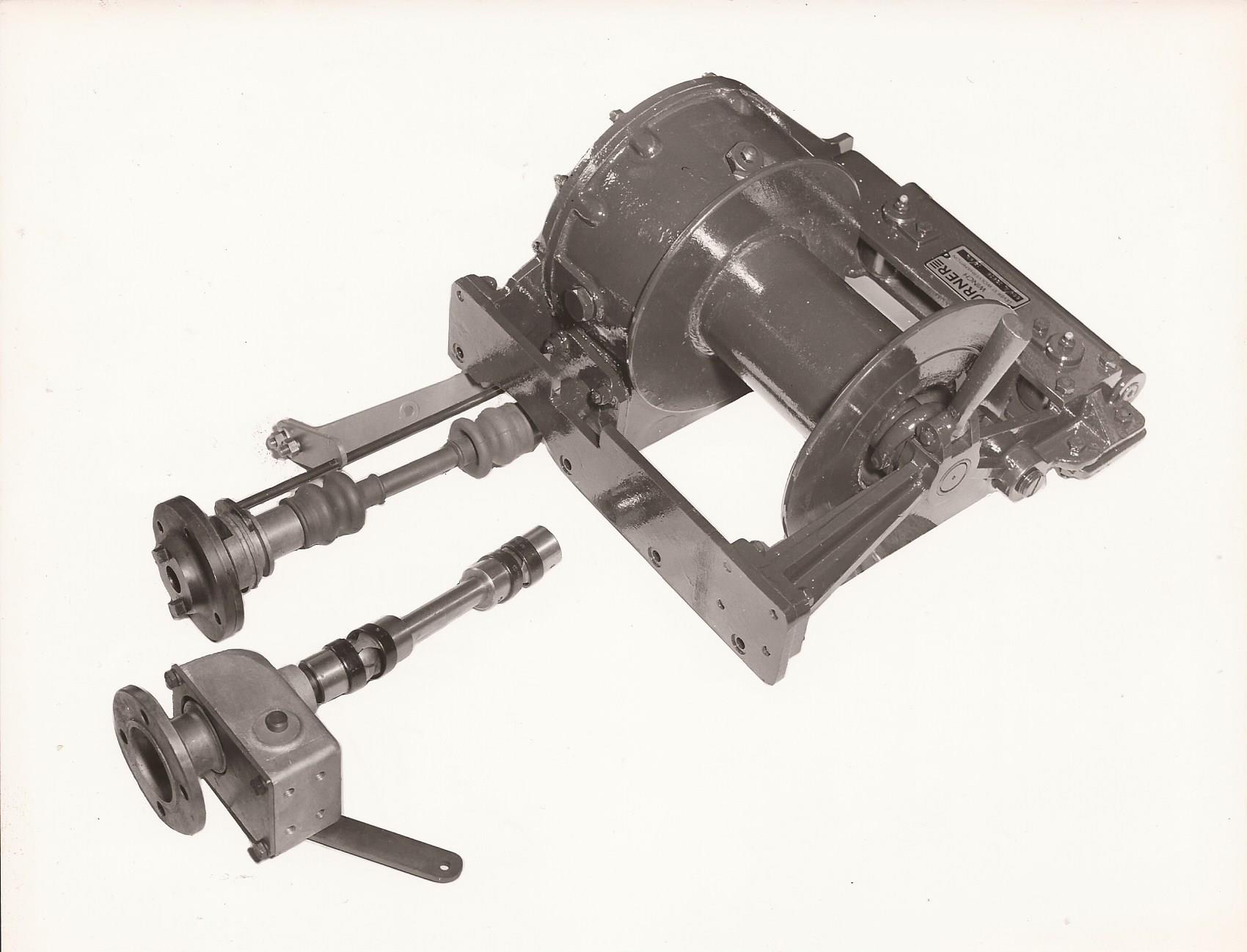

In the 1970’s JCB stopped using tractor backbones as the basis of their machines and introduced torque convertors in to the drive line. The torque converter drove a Warner reversing unit coupled to a Warner four speed truck gearbox. JCB asked Turner to provide an alternative transmission. They took the T4-200, as originally developed for the Leyland Terrier, removed the reverse gear and used the resulting “space” to widen the first and reverse gears. They also made up the sub assembly of converter, reversing unit and gearbox calling this the CRT4-200.

Whilst many thousands of these units were shipped from Wolverhampton to Rochester a small number went to Sanderson for their tele-handler machines.

The design did progress to be made more “compact” by putting a forward and reverse set of clutch pack, or a “shuttle unit” on top of the four speed transmission. This was eventually marketed to Manitou for their tele-handlers in 1985. The basic “compact shuttle” transmission has undergone a number of design revisions. The Caterpillar back hoe loader (BHL) machines became a major customer which resulted in them buying the Spicer European transmission division (the former “Turners”).