Company History

MAJOR EVENTS IN TURNER’S HISTORY

1859 Thomas Turner & Sons formed in Wolverhampton. (managed by J S Dumbell)

1902 The Dumbell’s purchase shares in Thomas Turner Co. in order to make cars.

1906 name changed to Turner Motor Manufacturing Company

1938 name changed to Turner Manufacturing Company

1968 Company floated on the stock exchange to become a Limited Company.

1974 Part ownership taken by the Dana Corporation. (“Spicer” brands introduced).

1978 Dana take 100% control. Generally regarded as the end of “Turners”

1996 Caterpillar acquire transmission division from Dana. The Tuner name was reintroduced as Turner Powertrain Systems.

2014 Production of Turner branded transmissions ceased in Wolverhampton with production being transferred to India

PRODUCTS MANUFACTURED BY TURNERS

CARS produced from 1902 to 1928.

Started with the Belgian “Miesse” steam car and then various petrol engine cars

MACHINE TOOLS

Produced from 1914 on in to the 1930’s.

Small lathes and Tool& Cutter grinding machines.

RECOVERY WINCHES

Produced from 1927 to 1982.

First customer was Guy Motors. Last Customer was Bedford. Many other military vehicles were fitted with winches having pulling capacity ranging from 1 to 20 tons.

AIRCRAFT LANDING LEGS & Aircraft sub contract work 1931 to 1970’s

Product started with“Oleo” type aircraft landing legs being produced under licence. Then their own design units. Helicopter rotor heads for Westland from 1952.

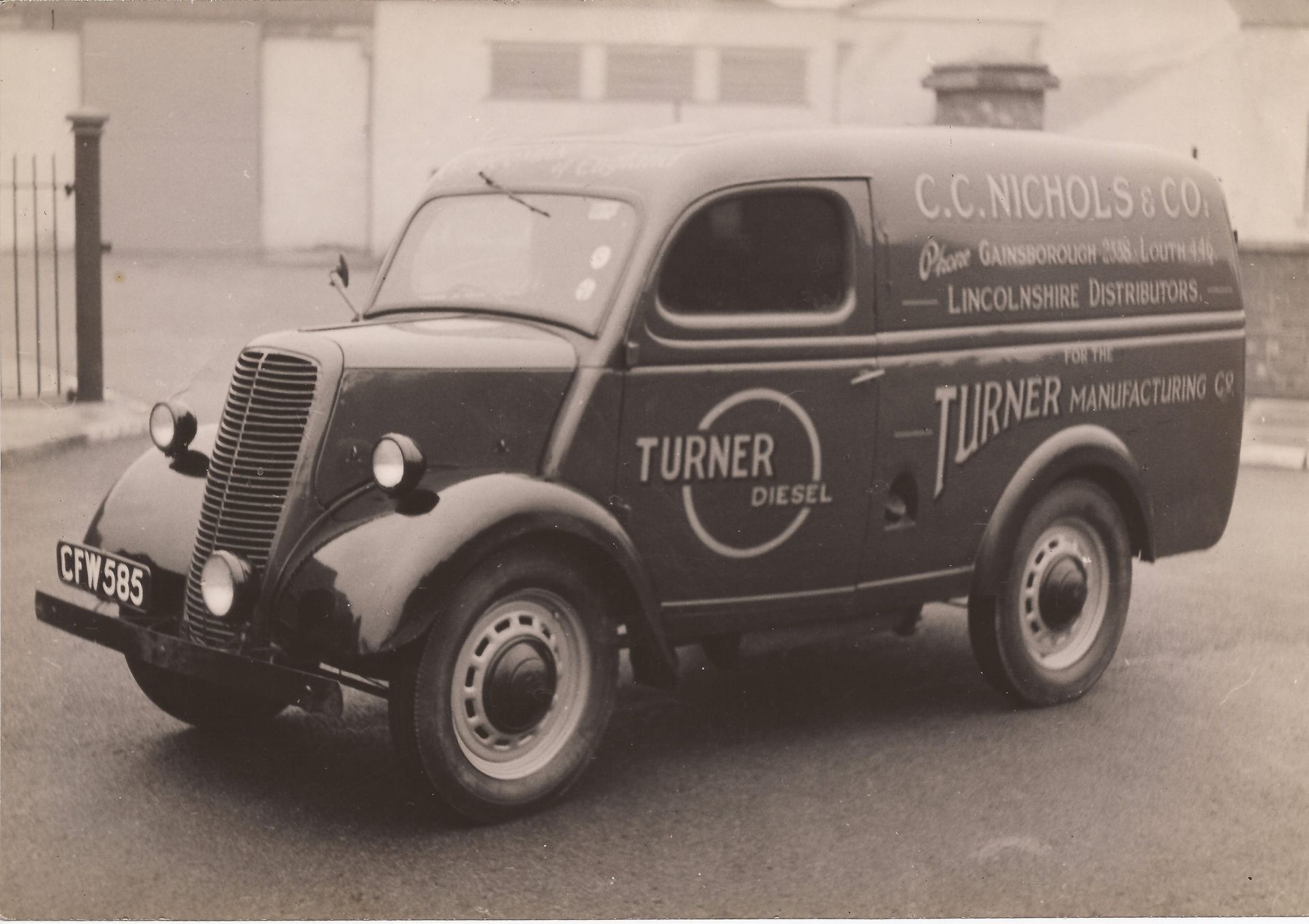

DIESEL ENGINES (four stroke V95 series).

Produced from 1946 to 1956

Designs started in 1944. Single, ‘V’ twin and V4 configurations.

LIGHT DELIVERY VEHICLES (the Byvan & Tryvan).

Produced 1946 to 1958

First sample machines used Royal Enfield engines then produced with the Turner “Tiger” engine. Marketing company LDV formed in 1947.

FARM TRACTORS (“The Yeoman of England”)

Produced 1949 to 1955 (but stock was still being sold into 1956!).

Production tractors used the 4V95 engine.

HYDRAULICS & PNEUMATICS

Produced 1952 to 1972 (?)

Initially made a range of valves etc and went on make to complete cargo handling systems for the first of the “Super Tankers”.

DIESEL ENGINES, Two stroke, to List design.

Produced from 1954 to 1958

First units obtained in 1952 but not produced until 1954.

Also used in a Front Wheel Drive VEHICLE unit with different bodywork attached.

TRUCK GEARBOXES

Produced from 1962 to 1998.

Started with a licence to produce Clark 265 which developed in to the T5-300 & T5-400 series of gearboxes. The T4-200 designed in 1968 with full use of taper bearings, pressed cup synchroniser cones etc. developed on in to the T5-290 and is also the basis of the Compact Shuttle type off highway boxes.

The above listing covers the major product groups of Turners. There are many other detail products or sub contract items that could be included. For more information about any of these please contact the web master.

A brief Turner history

TMC, the Turner Manufacturing Company Limited, Wolverhampton are perhaps best known on the preservation scene for the “Yeoman of England” farm tractor with its’ distinctive 4V95 series diesel engine.

There was a gathering / a display of these at the Tractor World Show on March 14th & 15th 2015 held at Malvern.

This company has a long history and was involved in many more things than just the Turner tractor.

The story starts in the early 1900’s when the Dumbell family decide to get in to manufacturing cars. To do this they invested in an existing company called Thomas Turner & Sons that had been formed in the middle of the 19 th century. {some sources say 1849 others say 1859} . They had small premises, little more than a workshop behind a house, in Gt Brickkiln Street in Wolverhampton. The Dumbells purchased larger premises in Lever Street then negotiated a licence to make a steam car from the Belgian Miesse Company. Initially a number of complete chassis were purchased to which bodies were fitted but they quickly moved on to making the complete car. The decision was made to produce cars fitted with petrol engines and in 1906 the company was renamed as Turner Motor Manufacturing. A variety of cars were made including some being joint ventures. Car production stopped for the duration of the first world war as Turners war efforts were to make large numbers of machine tools. After the war a short lived arrangement saw Turners making cars for “Varley Woods” and then they re-started production of their own cars. Car production came to an end by 1928 but it was not until 1938 that the name was changed to being Turner Manufacturing Company.

Three complete steam cars are known to survive one of which was owned by TMC and is now in the BCLM along with two petrol engine cars. One post WW1 Varley Woods car is known to have survived. In the 1960’s and 1970’s Turner apprentices helped to maintain the cars including taking the steam car on the London to Brighton run. The other Turner steamer that was seen out on that run is now located in the USA. The third Turner- Miesse is in the “Jurba” (?) museum on the Isle of Man.

In the 1920’s, whilst cars were still being produced, a venture in to the marine world was made when a small two stroke engine with an overhung crank called the Turner Bray was produced. As a publicity stunt one of these was used to power a small dingy across the English Channel.

A far more significant product was introduced in 1927 when Turners were asked to provide a recovery winch for a military vehicle chassis being developed by Guy Motors, also based in Wolverhampton. This resulted in a long association of Turners with the MOD producing winches with capacities ranging from 1 ton (for Land Rover type vehicles) up to 20 tons (as used on the Thornycroft Antar Mk3). Many vehicles were kitted out with Turner winches with the association with Bedford lasting until the late 1970’s.

Another addition to the product range was made in 1934/ 1936(?) when Turners became involved with the production of aircraft landing legs. The story goes that on return from a trip to Germany Turners MD complimented the pilot on his smooth landing to be told that it was helped by the Pneumatic, Fritz-Faudi, type of landing legs fitted to the plane for which Turner duly gained a licence to manufacture. This was quite fortuitous timing as with the outbreak of WW2 Turners rapidly became a major supplier of undercarriage as fitted to a variety of planes along with their winch production.

The loss of aircraft landing leg production left Turners looking for an alternative peace time products. One of these was the range of four stroke diesels known as the “V95” series first exhibited at the Smithfield Show in 1946. The 4V95 engine from this range became the basis of the tractor which started production in 1949.

The Turner Yeoman of England tractor was one of the earliest to be produced using an "in house" designed multi-cylinder diesel. Yes it was expensive and the author has to agree that it was not a commercial success. Much publicity is given to a number of reliability issues that dogged the tractor but the author feels that perhaps a number of those could be attributed to the ground breaking use of the diesel engine with its high lugging power and capability of working much harder than the currently available petrol engine tractors. The author also feels that pretty much all of the reported problems were fixed by the time the Mk3 version was introduced at serial number 900. However, it would seem that the old saying that there is no such thing as “bad publicity” is true as the tractors remain highly desirable in the preservation world.

As well as the four stroke V95 diesels Turners also became involved with a two stroke blown diesel designed in Austria by Dr List of Jenbach. These engines had a high power to weight ratio due to the extensive use of aluminium for the castings and the two stroke cycle made them very simple in construction. Turners produced and marketed the two and three cylinder versions of these engines known as the L40 and L60. The number 40 or 60 relating to the nominal power output. As a publicity stunt for these engines a Land Rover fitted with an L60 was driven overland from Wolverhampton across the Sahara Desert down through Africa to Nairobi. 2015 is the 60th Anniversary of that expedition titled “Operation Enterprise”.

The 1950’s were a period of major changes for TMC. As well as the diesel engines and tractors a number of other products were tried. A front wheel drive unit using the L40 engine was prototyped. A range of “light Delivery Vehicles” were built using basically a front wheel drive motorbike as the power source. Winch production had a sudden boost to support the vehicles needed for the Korean War. The diesel engine and tractor production stopped but major sub contract work was gained to supply parts to Ford tractors. The equipment used to produce the L40 and L60 engines saw a short period of being used to supply “kits of major parts” for the Perkins 4.99 engine.

The 1960’s saw the last major change of product for TMC. To support the high volume UK production of light weight commercial vehicles such as the Ford D Series and the Bedford TK Turners took a licence to produce the Clark 265 five speed truck gearbox.

To compete with the lightweight Ford and Bedford trucks Leyland came up with the “Redline Range” produced at Bathgate in Scotland. For the lightest vehicle in the range, the Terrier, Turners designed a completely new fully synchronised range of 4 and 5 speed transmissions. The T4 and T5-200 gearboxes had a number of innovative features including all shaft supports being on taper roller bearings and the synchronisers having separate pressed steel cups. The box was updated and revised as the Leyland truck range progressed through the “Road Runner” on to the Leyland 45 series.

The T4-200 was also modified to be the four speed part of the transmissions used to replace the tractor backbones for JCB, the CRT4-200. The initials standing for Converter, Reverser, T series 4 speed transmission with a 200 lbsft rating. Some of these transmission units were sold to Sanderson. At a later date the transmission was made more “compact” by putting the four speed syncronised gear section underneath the forward and reverse, Or “shuttle” clutch pack sections.

Manitou were the first production customer for the “Phase 1 Compact Shuttle” and the same basic transmission with progressive updates continues to be used in construction and agricultural machinery.

Various Turner truck gearboxes were used for agricultural applications such as the driving chains of ditch digging machines and the Clayton Buggy crop spraying machine. Synchroniser from Turner truck gearboxes were also used by International Harvester and Leyland.

In 1978 Turners were sold to the Dana Corporation and then traded as their European Spicer Transmission Division. That in turn was eventually sold to Caterpillar but the old TMC parentage of the transmission designs still in use is evident.