The Turner Manufacturing “Yeoman of England” tractor

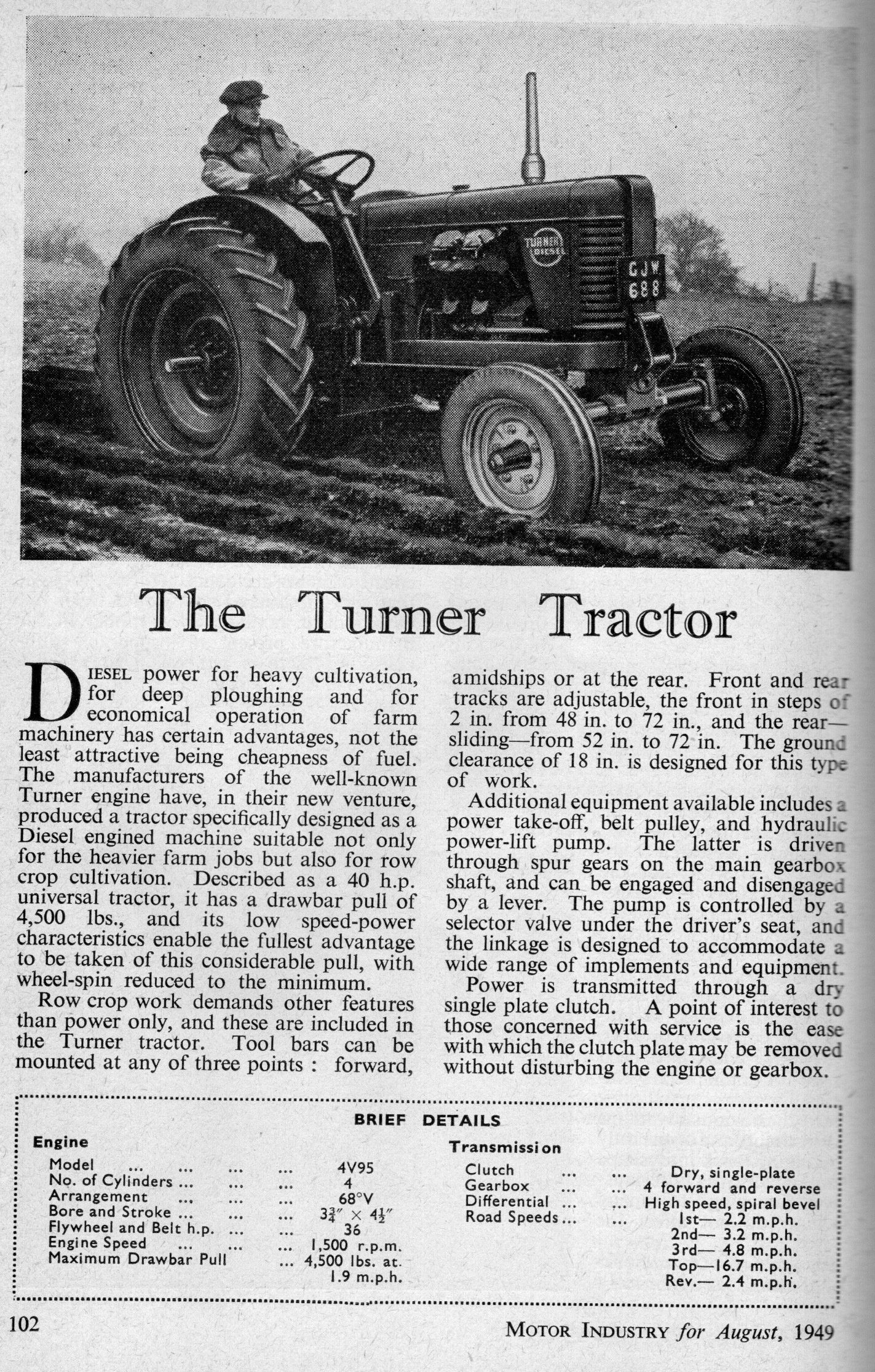

The basis of the Turner Manufacturing tractor is the V95 series of diesel engines. Patents for details of the engines design were filed by Turner Manufacturing in February 1944 but engine production was started in 1946 firstly in V-twin and single cylinder form. A V4 version was added in 1948. The engines were marketed for a variety of industrial and marine applications and had an output of 7.5 to 9 HP per cylinder depending on the duty cycle and rating applied.

A farm tractor was considered as another application or outlet for the engines and prototypes were made using the 2V95 and 4V95 engines. These were tested on farms in the Wolverhampton area where Turner Manufacturing were based. Detail work was carried out on the engines to provide a rating suitable for the farm tractor application during 1949. A patent fee or royalty had to be paid to Freeman Sanders. This “second” version of the engine is why the engine serial numbers are stamped as “4V2” and why the first production Turner Manufacturing tractors are called the MK2.

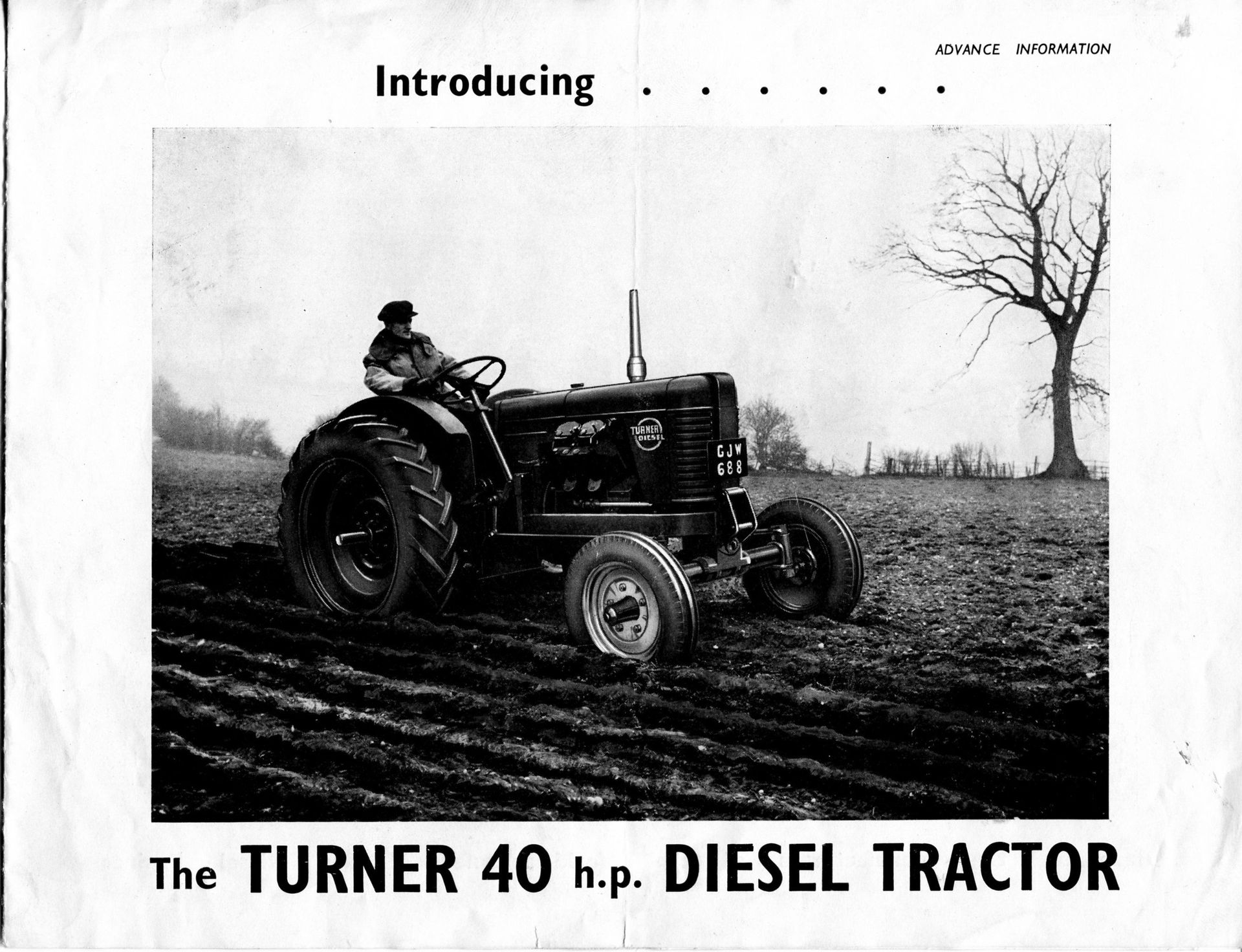

The prototype Turner tractor with the 2V95 engine has survived and is still on the same family farm where it was tested. The prototype Turner tractor with the 4V95 engine has not survived. There are some photographs which show different front chassis and axle configurations. The tractor was launched at the Royal Show held at Shrewsbury in 1949. The Turner tractor was one of the earliest to be produced using an in house designed multi-cylinder diesel. Much was made of the “lugging power” of the diesel engine in the advertising material. The Turner tractor was marketed as a “40HP” machine with that rating being determined at the “Nebraska Trials”.

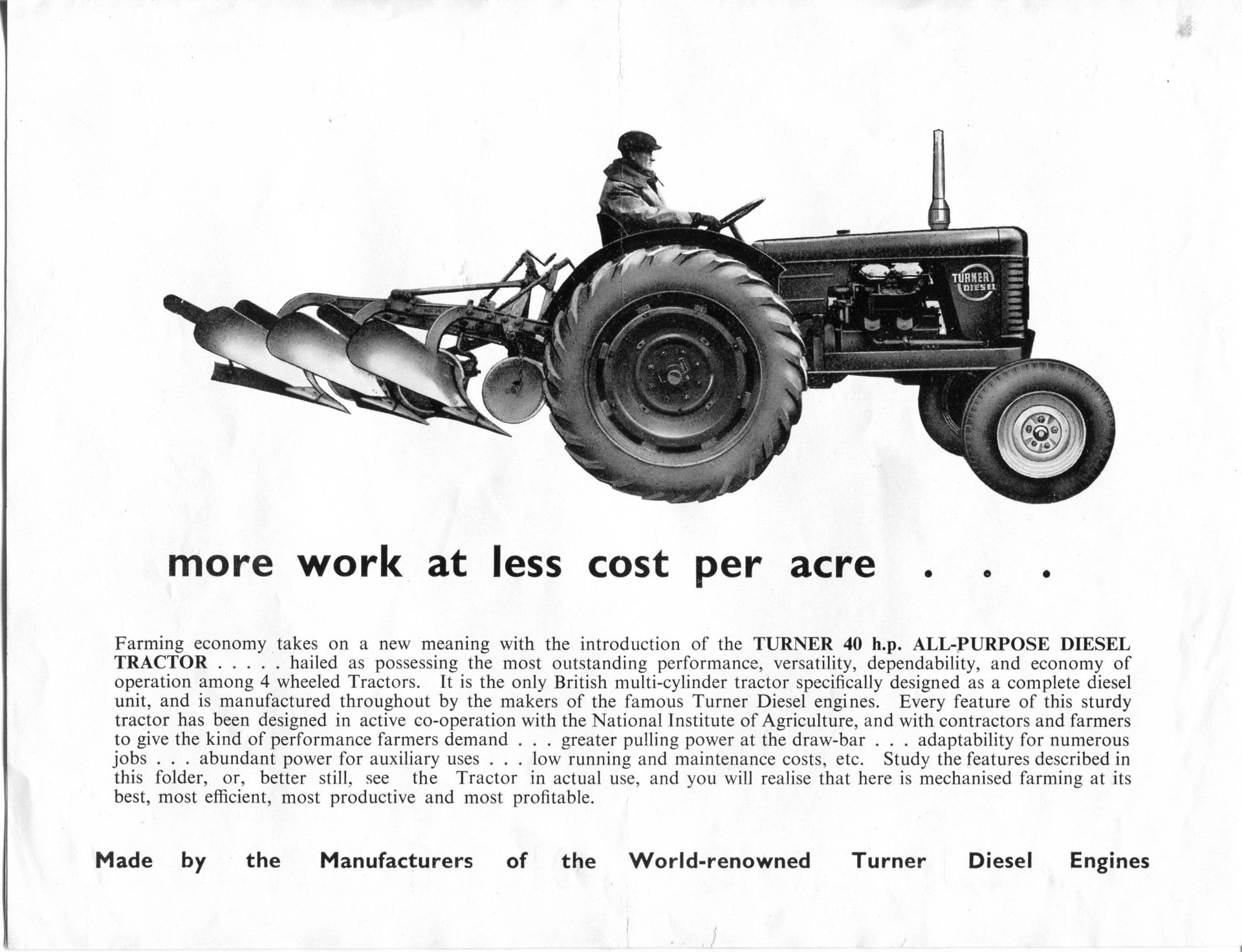

A range of approved implements was marketed for use with the tractor. Ploughs from Adrolic had the Turner name cast into the main legs. A cab to suit the Turner tractor came from Scottish Aviation. A range of tool bar equipment from H Leverton & Co of Spalding was available. The Denning semi-mounted mower was “approved” as was the mid mounted Featherstone mower. Brochures also show winches, saw benches and scraper blades.

From the outset the tractor was expensive when compared to the 27 HP (non diesel) offering from Ford. There is no way that the product of a small entrepreneurial based company in Wolverhampton could have ever competed on price against the production capacity and resources of a multi-national such as Ford. Also, much is made in published information about various “reliability problems” which the Turner tractor suffered. So, a few of these will be discussed here.

A problem with the cooling was encountered whilst on static belt work on trials at the National Institute of Agricultural Engineering. This “static work” problem was cured by the introduction of a larger radiator at tractor chassis serial number 352 in July 1950 (the last Mk. 2 to be built, which is chassis number 351 has survived into preservation and is located in Suffolk). The tractor designation was changed to the MK2A and the aluminium front cowl was replaced by a pressed steel item at the same time.

The initial use of a (cheap?) paper element air filter caused problems. This was replaced by an oil bath type unit. It is not clear when the oil bath type air filter was introduced and it would appear that a number of early tractors have been retrofitted.

It is “reported” that head gasket failures were “frequent”. Was part of this simply due to the market being unfamiliar with the higher compression ratio of the diesel which needed the cylinder head bolts to be tightened to 80lbsft? Was a part of this due to the initial design of cylinder head shape which gives a narrow section to the gasket? The design of the cylinder head and the associated gasket were changed at serial number 900 when the MK3 version of the engine was introduced. The cylinder liners were changed from dry to wet at the same time.

The 'Yeoman of England' tractor transmission is reported as being “prone” to failure mainly in the crown wheel and pinion area. The detail design of the gearing was certainly changed during the life of the tractor because of these problems but was part of the problem caused by the “lugging capacity” of the diesel engine being fully exploited? The design of the gearing may well have been inadequate for the duty cycle experienced with a fully utilised diesel engine. It is not really my intention to criticise the “opposition” but it would appear that the “competitive” 27HP tractor had a much more robust final drive as they could be repowered with the P6 Perkins engine with no apparent problems.

There are a number of other reported problems that could be discussed but it is clear that despite these the Turner Manufacturing Yeoman of England tractor is highly prized on the preservation scene. A total of just over 2,100 tractors were built and efforts to establish just how many of these have survived are continuing. Please contact the web master if you are the owner of a “Yeoman” or you know to any surviving examples.

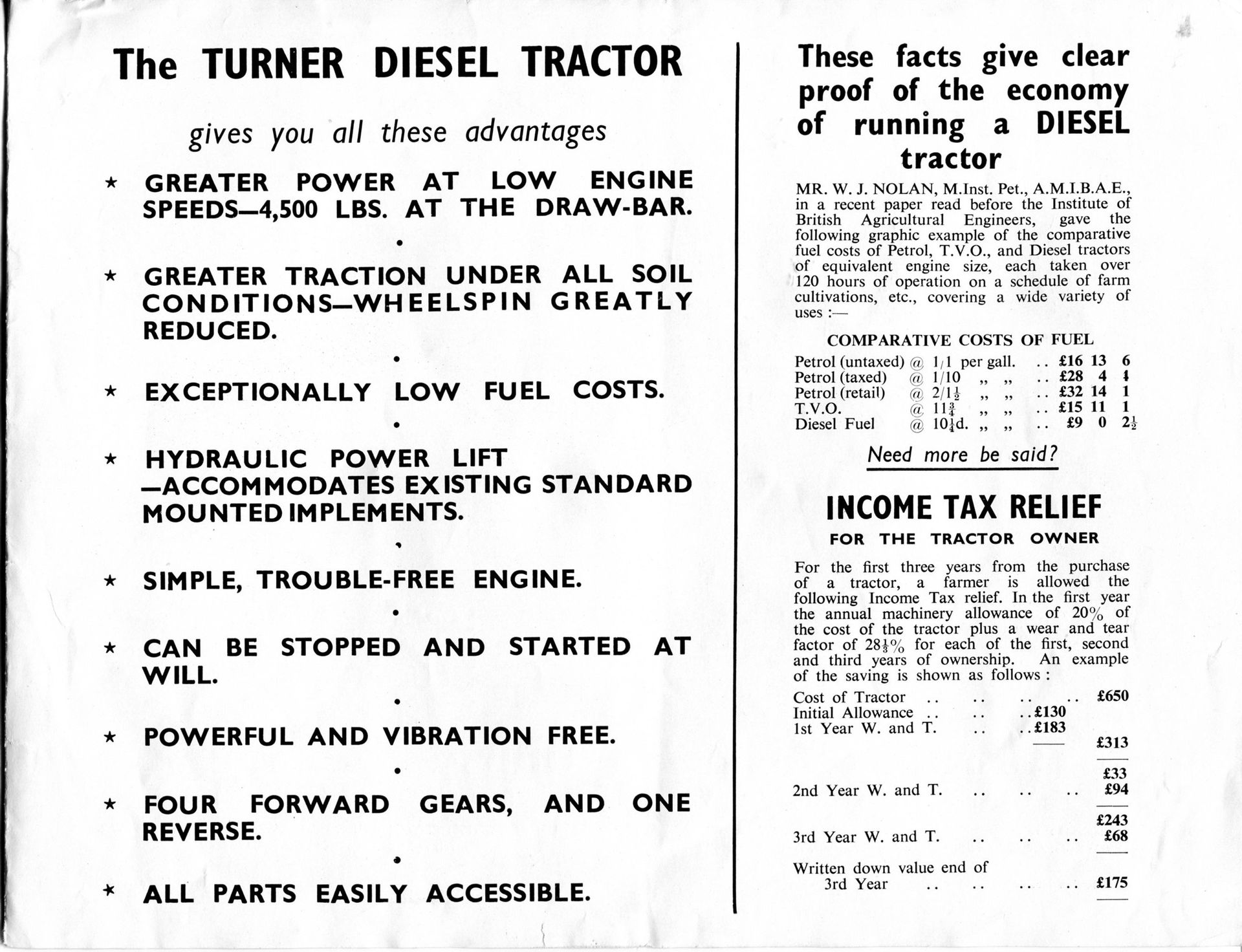

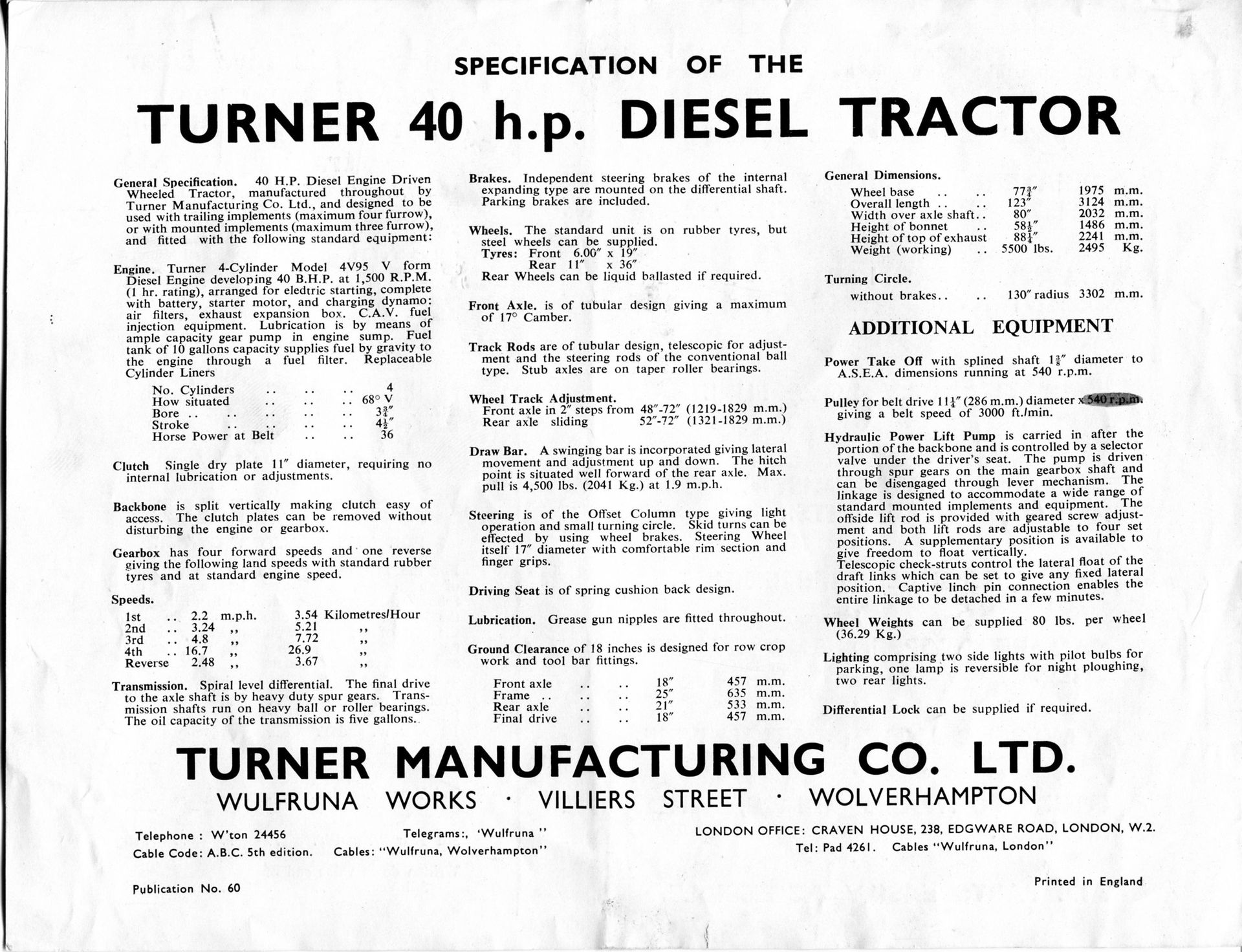

I have just 'discovered' the document in the four pictures below:-

The following picture is a Yeoman out in Brasil, hopefully more information to follow:-

Front view of a Yeoman tractor:-

Side view of a Yeoman:-

Yeoman with home made cab seen in a sale in Cambridgeshire in 2013:-

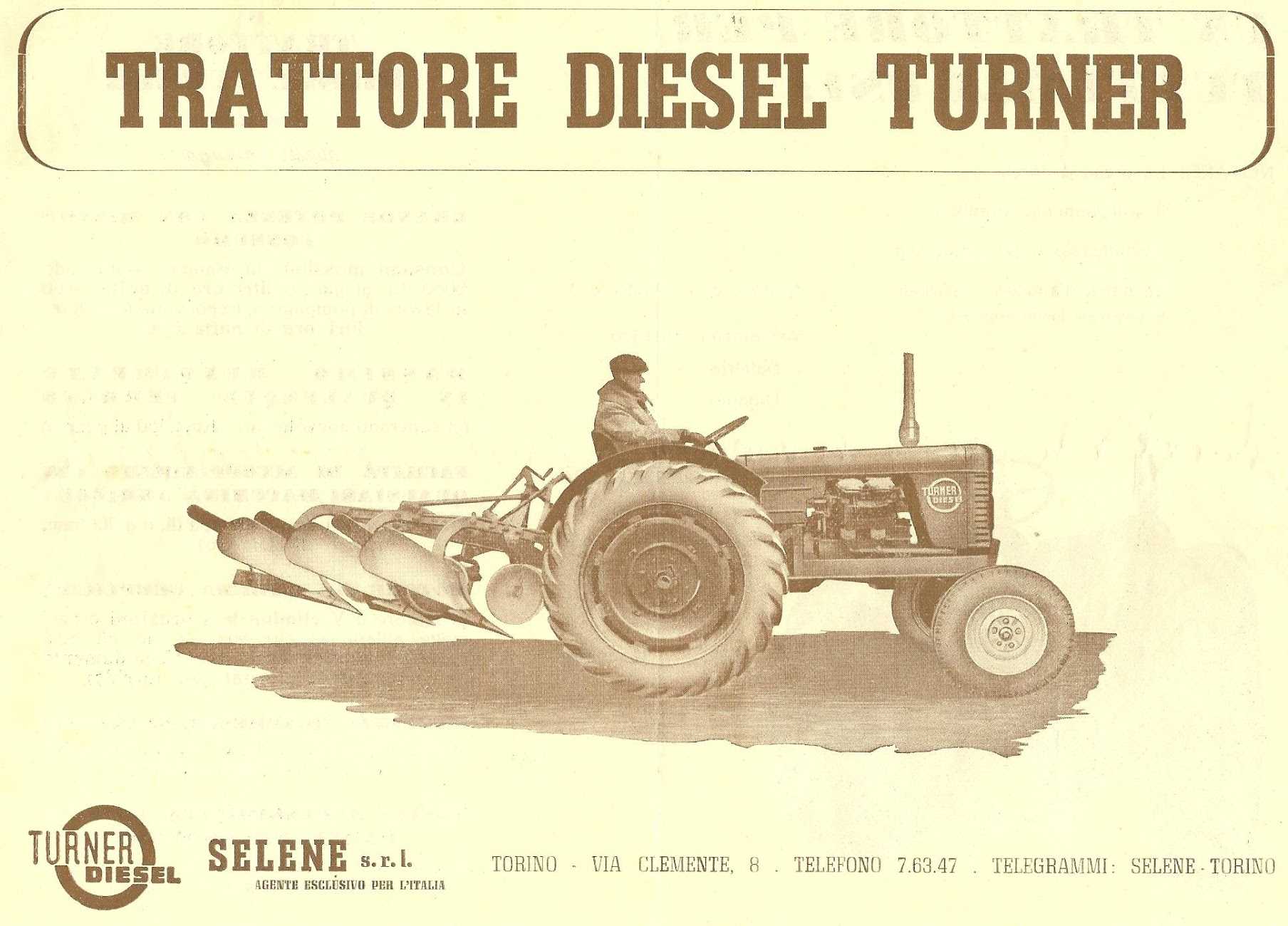

Italian dealer's advert:-

LINKS TO TRACTOR PHOTO'S

The following three links to photo's are provided by an anonymous owner:-

WHOSE IS IT???

The photograph below was taken by a guy who organises off-roading ventures for Land-Rover owners somewhere outside Eyam in Derbyshire. The far tractor is a Yeoman and if anybody visiting this site knows who owns this tractor could you please send an EM

The following series of pictures are 'official' Turner promotional ones:-

Yeoman At Fraserburgh 2007

Yeoman towing a Levertons of Spalding manufactured cultivator.